Description

Views: 1148

Acrylic marine fabric is 100% acrylic solution dyed, teflon treated, synthetic fabric with traditional canvas appearance. Teflon impregnation treatment, providing water resistancewith a water column rating of 350mm, while still allowing for some breathability to manage moisture and dampness. And more, we added PU coated backing for this collection of fabric. This special PU (polyurethane) resin coating adds a barrier layer to the underside of the acrylic fabric increasing its water column rating from 350mm to 1000mm. So this material can avoid water leaking in heavy rains.

Solution dyed acrylic is the most colour stable cloth available with the highest UV resistance. Acrylic marine fabric is a synthetic woven material, supplied in a range of finished, designed for outdoor applications. A highly technical but natural canvas appearance makes this fabric perfectly suited to withstand the rigorous of the outside and marine environment. The fabric’s durability is further enhanced by its resistance to mildew, water, stretching, and shrinking, withstand temperature and weather variations while maintaining a popular canvas look.

DOUBLE LAYER ENHANCED WATER BARRIER TREATMENT FOR MARINE USE

| 1. Teflon or Carbon Zero water resistant solutions | |

|

Teflon® PTFE treatment, the acrylic fiber is soaked with a Teflon-based coating that has the remarkable property of being both hydrophobic (water shedding) and oleophobic (oil shedding). Water cannot readily wet out the surfaces. The water droplets behave like mercury when confronted with the coated surface. This creates a barrier effect against common growth of mould and black dot mildew and reinforces the water-repellent properties of the fabric. Furthermore, it delays the adherence of dirt in the fabric. |

| Carbon zero is designed to replace traditional Teflon coatings, it is an advanced water-resistant treatment developed to provide superior fabric protection without the environmental drawbacks associated with fluorocarbon-based treatments like Teflon. This technology ensures that your outdoor fabrics remain durable, clean, and vibrant while significantly reducing their ecological footprint. | |

| 2. PU coated backing | |

| The special resin coating adds a barrier layer to the underside of the acrylic canvas increasing its water column rating to 1000mm plus. The PU coating is the most popular of finishes supplied into the marine market, with its main use being Sprayhoods and Enclosures. | |

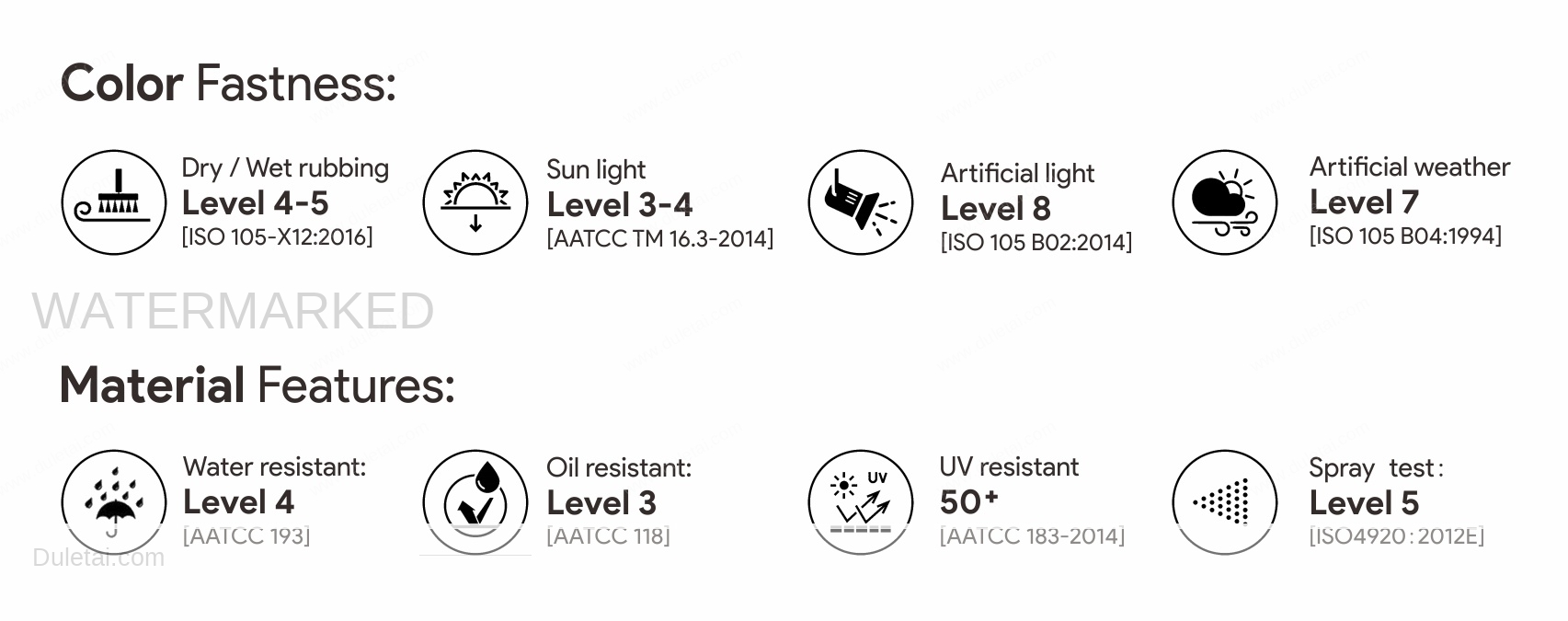

TECHNICAL DATA SHEET:

| Acrylic Marine fabric | DuraSuntex DLT-AM1000Series | |

| Material: | 100% acrylic solution dyed |

| Technics: | Teflon® PTFE treatment / Carbon zero / Water proof back layer |

| Width: | 120cm (47″) / 150cm (59″) |

| Weight: | 300gsm |

| Roll length: |

60 / 100 meters |

| Color fastness: | Level 7-8 (EU standard) |

| UV resistance: | 2000+ Hours (US standard) |

| Water pressure: | >1000mm [Hydrostatic ISO 811:2018] |

| UV Test: |

50+ [Rated UPF AATCC 183-2014] |

| Tearing strength: | 42N Warp / 38N Weft |

| Tensile strength: | 870N Warp / 1000N Weft |

| Alcohol Test: | Level 4 [0.6cm 10s 45° AATCC 193] |

| Water repellency: | Level 5 [Spray test: 20±2℃ ISO 4920:2012E] |

| Oil Test: | Level 3 [0.6cm 30s 45° 27.3m N/m AATCC 118] |

| Life span: | 10+ years |

5 Years Limited-Warranty

Our fabric guarantee 5 years limited warranty. Warranty coverage just include fading or losing colors due to the color performance degradation in normal environment. The warranty does not cover deterioration of any kind due to fire accidents, burns, abusive use, malfunction, negligence, vandalism, perforations, or other acts of God. The warranty does not cover any labor installations.

Download Digital Catalogue Download Digital Catalogue |

|

ACRYLIC MARINE FABRIC FEATURES:

- Excellent colour stability

- High resistance to sunlight and outdoor conditions

- Maximum resistance to tearing due to stretching

- Weather resistant to extreme temperature

- Tightly woven finish with traditional canvas appearance

- UV and fade resistant

- PU water proof backing

- Mould and mildew resistant

- Bleach cleanable

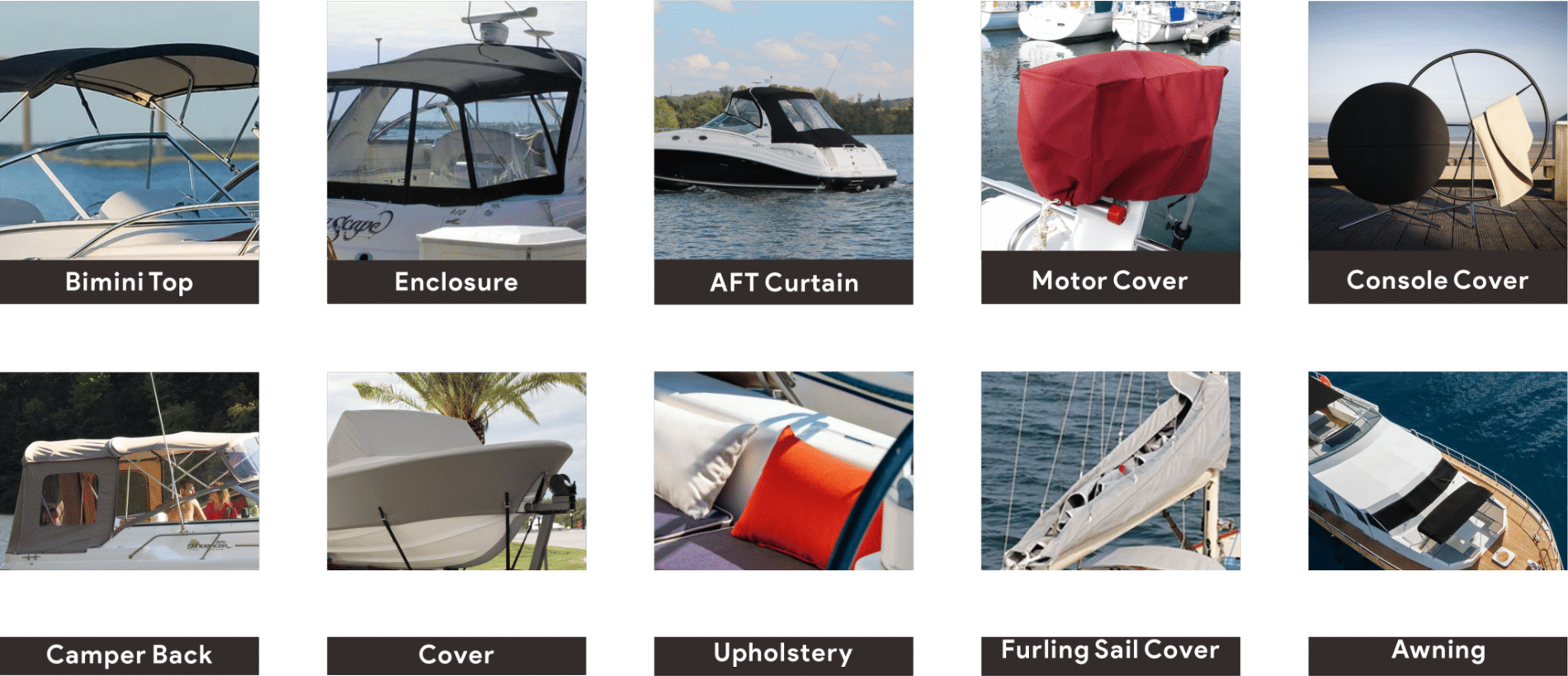

APPLICATIONS:

|

|

|

CLEANING INSTRUCTIONS:

- Eliminate dirt by gently brushing or vacuuming the fabric.

- Occasionally use a water and soft soap solution to clean the fabric.

- Maximum water temperature of 30°C

- Apply to the fabric and then rinse with running water.

- Let the fabric dry completely before storing.

- Do not use solvents or abrasive detergents.

- Do not use alkaline detergents, as alkalinity can dissolve acrylic fibers, causing fabric fading and compromising fabric strength.

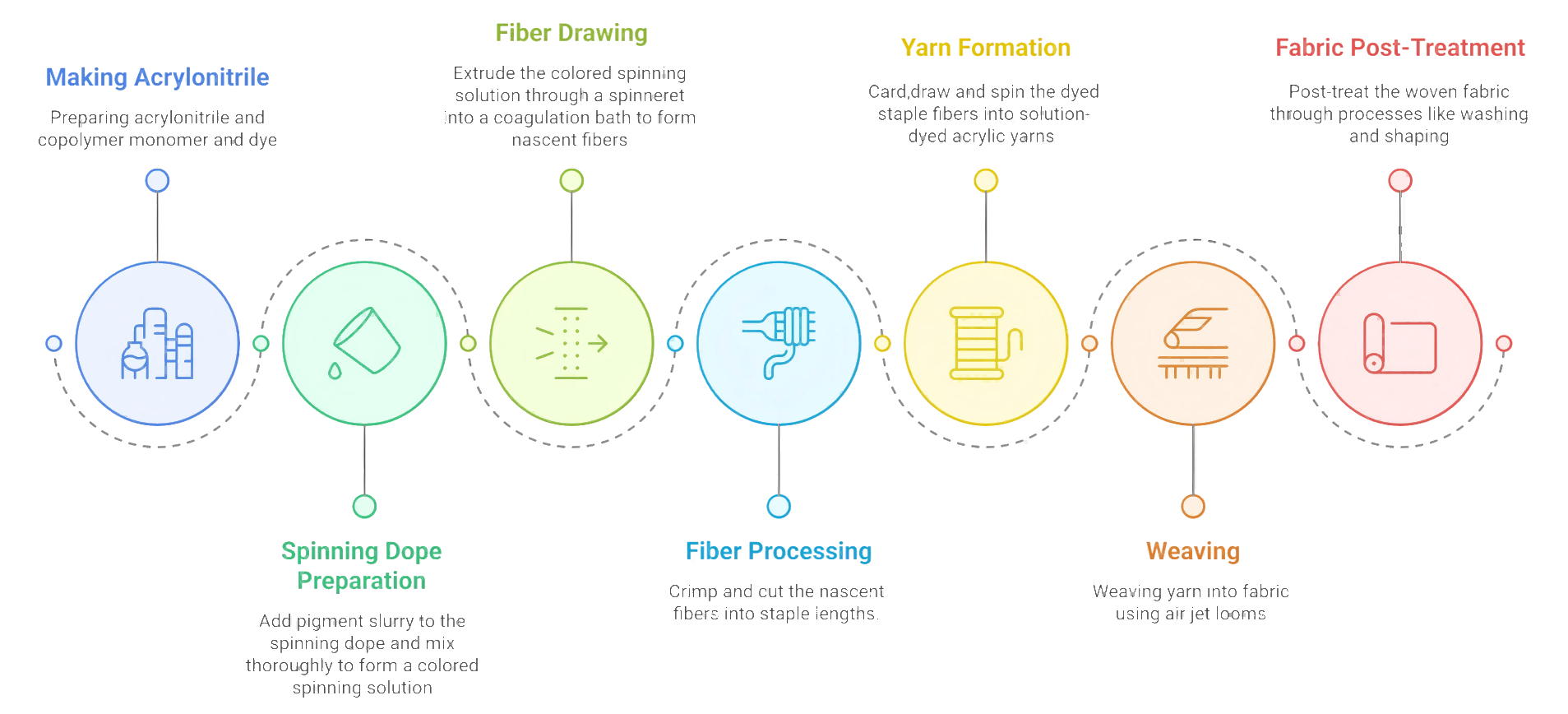

What does “100% solution dyed” mean?

DuraSuntex DLT-AM1000 fabric is made with 100% solution dyed / Dope dyeing technology. It integrates pigments during the polymer extrusion stage, fundamentally altering color fastness compared to conventional post-production dyeing methods. The stage at which color is introduced significantly affects the final fabric’s durability, resistance to fading and rub fastness. Below is a structured analysis:

| STEP | Dope Dyeing | Stock Dyeing | Fiber Dyeing |

Yarn Dyeing |

Fabric Dyeing |

| Making Acrylonitrile | |||||

| Spinning Dope Preparation | Pigment slurry is added to the spinning dope and thoroughly mixed to form a colored spinning solution. | ||||

| Fiber Drawing | |||||

| Fiber Processing | Dyeing nascent fibers after crimping and cutting | ||||

| Yarn Formation | Dyeing fibers before they are spun into yarns. | ||||

| Weaving | Dyeing yarn before weaving. | ||||

| Fabric | Dyeing the fabric after weaving. | ||||

| Result | 5 Years Colour Fastness |

2-3 Years Colour Fastness |

1-2 Years Colour Fastness |

1 Years Colour Fastness |

0.5-1 Year Colour Fastness |

There are many types of outdoor fabrics on the market labeled as “Solution-dyed.” In fact, they vary significantly based on the dyeing stage—ranging from dope dyeing, stock dyeing, fiber dyeing, yarn dyeing, to fabric dyeing. The colorfastness of these methods can range from as little as 0.5 years to up to 5 years. However, it is extremely difficult to distinguish between these dyeing techniques just by looking at the surface of fabric sample . The cost difference between these dyeing processes can be substantial. Even more concerning, some manufacturers use polyester yarns hidden in the weft to reduce production costs while maintaining the appearance of acrylic fabric. Therefore, do not be misled by low prices.