Flame Retardant PVC Tarpaulin

Views: 50

Flame retardant PVC tarpaulin is a special type of polyester fabric combined with PVC and fire-resistant additives. Unlike regular tarps, it slows down or stops fire from spreading, making it essential for places where fire safety is critical.When fire touches it:

✅ Slows down flames

✅ Stops burning when fire source is removed

✅ Protects what’s underneath

What’s Inside?

Flame retardant PVC tarpaulin is manufactured through a specialized process that involves:

- Base Material: High-strength polyester canvas that provides structural integrity

- PVC: Coated or laminated polyvinyl chloride (PVC) layer

- Flame Retardant Additives: Specific chemical compounds added during manufacturing

- Additional Additives: Accelerators, mildew inhibitors, anti-aging agents, and anti-static agents

| Component | What It Does |

|---|---|

| Polyester Fabric Base | Makes it strong and tear-proof |

| PVC Plastic | Makes it waterproof & flexible |

| Fire-Stop Chemicals | Prevents flames from spreading |

| Extra Protectors | Fights UV rays, mold & aging |

| Core Technology and Materials | ||

| Antimony Trioxide (Sb₂O₃) | Smoke Reduction | Dripping Control |

| Added to the PVC formulation to boost flame suppression. | Reduce toxic fume generation by up to 50% during fire exposure. | Reduced calcium carbonate formulation minimizes melt-dripping behavior. |

| Works with halogen compounds to form protective char barriers during combustion. | Minimize release of hazardous chemicals (including HCl gas). | Eliminates secondary fire hazards from falling molten material. |

| Significantly increases oxygen index (LOI) to achieve self-extinguishing properties. | Create clearer evacuation pathways in emergency scenarios. | Maintains fabric structural integrity at high temperatures. |

️ Where it’s used?

| Industry | Applications |

|---|---|

| Transport | Truck/train covers, cargo protection |

| Construction | Temporary shelters, scaffolding covers, debris containment |

| Events | Festival tents, stage backdrops, exhibition dividers |

| Storage | Warehouse covers, machinery protection |

| Public Spaces | Hospital barriers, school safety installations |

Global Safety Standards

| Standard | Country/Region | Key Classifications |

| Euroclasses (EN13501-1) | European Union | A1-F, s1-s3, d0-d2 |

| M Classification | France | M0-M4 |

| B Classification (DIN4102) | Germany | B1-B3 |

| NFPA 701 | United States | Test Method 1 & 2 |

| AS/NZS 1530 | Australia/New Zealand | Part 1-4 |

| Key Tests: How fast fire spreads / How long it keeps burning / How much smoke it makes | ||

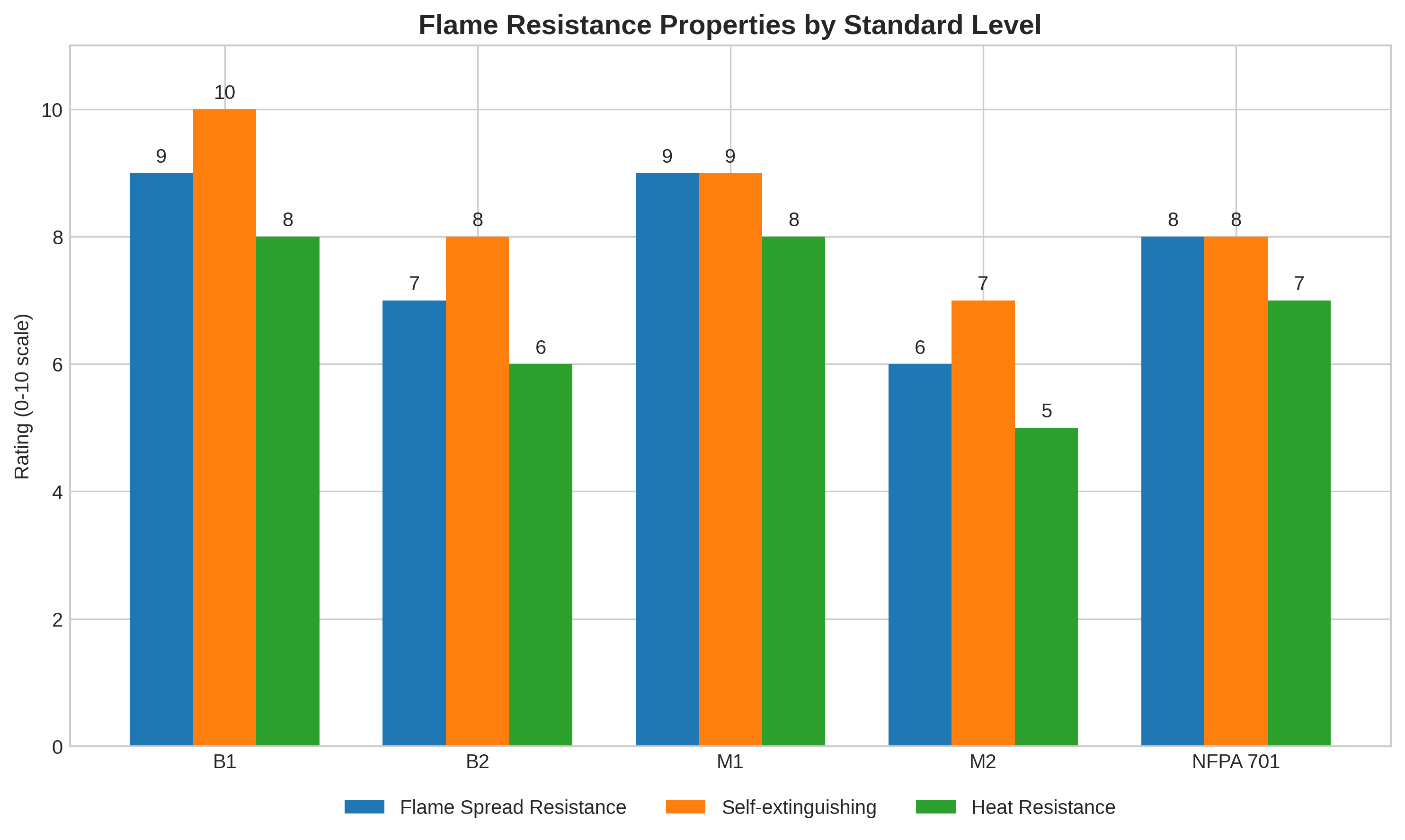

Flame Retardant Levels and Requirements

| Level | Description | Requirements |

| B1 | Fire retardant, self-extinguishing | Difficult to ignite, limited flame spread |

| B2 | Normally flammable, self-extinguishing | Less fire resistant than B1 |

| M1 | Non-flammable combustible materials | Excellent fire resistance, low flammability |

| M2 | Flammable materials with low flammability | Medium fire resistance |

| NFPA 701 Test 1 | For materials ≤700g/m², single-layer fabrics | Pass flame propagation test |

| NFPA 701 Test 2 | For plastic films, vinyl-coated fabrics | Pass flame propagation test for heavier materials |

Choosing Your Protection Level

| Fire Danger Level | Best Standard | Good For… |

|---|---|---|

| High risk | B1 or NFPA 701 Method 2 | Welding areas, chemical storage |

| Medium risk | NFPA 701 Method 1 | Event tents, truck covers |

| Basic protection | General flame retardant | Temporary covers, indoor use |

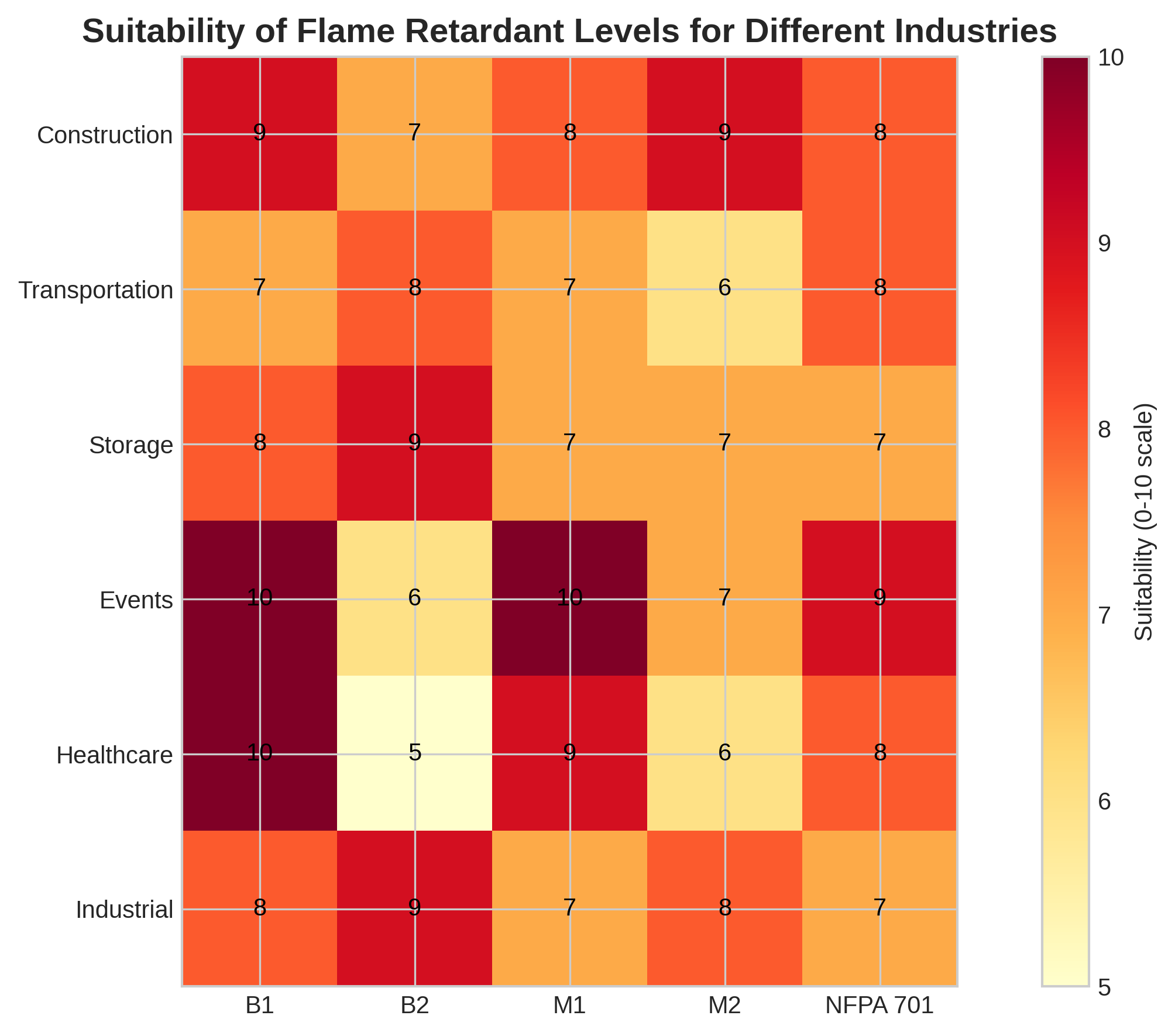

Applications of Different Flame Retardant Level Materials

| Level | Common Applications | Industry Sectors |

| B1 | Public buildings, exhibition halls, theaters, hospitals | Construction, Events, Healthcare |

| B2 | General industrial use, warehouses, temporary structures | Industrial, Storage, Transportation |

| M1 | Public buildings, high-risk environments, theaters | Events, Entertainment, Public facilities |

| M2 | Commercial buildings, standard requirements | Commercial, Industrial |

| NFPA 701 | Commercial buildings, public spaces in the US | Commercial, Public facilities, Events |

- Published in Technology

Weather resistant PVC knife coated tarps

Views: 336

Weather-resistant PVC knife-coated tarps are a popular choice for outdoor applications such as truck covers, boat covers, and tents. PVC tarps are made of high-quality vinyl coated with polyester mesh fabric that makes them strong and durable. They are resistant to water, UV rays, mildew, and abrasion.

Here are some examples of weather-resistant PVC knife-coated tarps:

- Heavy Duty PVC Tarpaulin: This tarp is made of high-quality PVC material that is resistant to water and UV rays. It is perfect for outdoor applications such as truck covers, boat covers, and tents.

- Super Heavy Duty PVC Tarpaulin: This tarp is made of high-quality PVC material that is resistant to water, UV rays, mildew, and abrasion. It is perfect for heavy-duty outdoor applications such as construction sites and industrial settings.

- Published in News

PVC vinyl for Tonneau Cover

Views: 261

Start with an introduction that explains what a tonneau cover is and why it is important. You can also provide some background information on vinyl tonneau covers.

- Benefits: Discuss the benefits of using a vinyl tonneau cover. You can talk about how it protects the cargo from weather elements and theft, and how it can improve the fuel efficiency of your truck.

- Types: Describe the different types of vinyl tonneau covers available in the market. You can talk about soft roll-up covers, hard folding covers, retractable covers, etc.

- Features: Discuss the features of vinyl tonneau covers that make them stand out from other materials. You can talk about their durability, ease of installation, and resistance to water and UV rays.

- Maintenance: Provide some tips on how to maintain a vinyl tonneau cover. You can talk about how to clean it, how often to clean it, and what products to use.

- Conclusion: End your article with a conclusion that summarizes the main points you discussed in the article.

- Published in News

The best Tonneau Cover fabrics for different weather conditions

Views: 343

Tonneau covers are an essential accessory for truck owners. They protect the cargo from weather elements and theft. The best tonneau cover fabrics for different weather conditions are:

- Vinyl: Vinyl is the most popular material for tonneau covers. It is durable, easy to clean, and can withstand harsh weather conditions. It is perfect for areas with high humidity and rainfall.

- Canvas: Canvas is a heavy-duty fabric that is resistant to water and UV rays. It is ideal for areas with extreme heat and sunlight.

- Aluminum: Aluminum is a lightweight and durable material that can withstand extreme weather conditions. It is perfect for areas with heavy snowfall.

- Fiberglass: Fiberglass is a strong and lightweight material that provides excellent protection against weather elements. It is ideal for areas with high winds.

- Published in News