Description

Views: 83

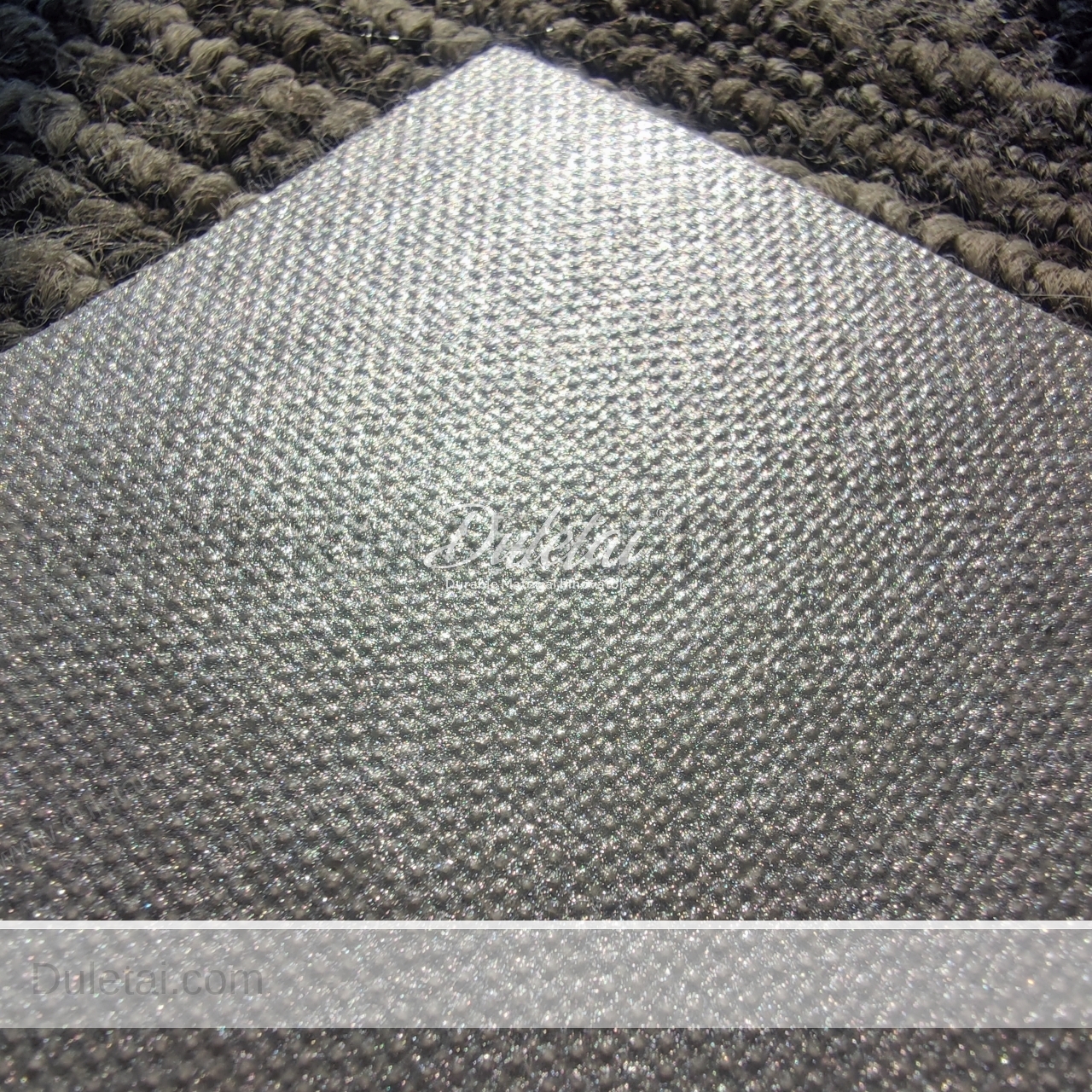

Tensile membrane structure materials is a coated woven fiberglass membrane that is extremely durable and tolerant of even the most extreme weather elements. The woven fiberglass gives PTFE coated glass fiber its mechanical strength and providing the membrane with maximum flexibility. PTFE fiberglass membrane can be installed in climates ranging from the frigid arctic to the blistering desert heat with a life expectancy of up to 25 years. PTFE fiberglass coating is chemically inert, capable of withstanding temperatures from -100°F to +450°F (-73°C to +232°C). The low-surface of the material creates a surface that is cleaned by rainwater. The principal element that differentiates PTFE coated glass fiber from conventional glazing is its advantageous shading coefficient. As lighting levels increase, even cooler climates can realize overall energy savings using PTFE coated fiberglass. In very warm climates, even low lighting levels make tensile membrane structure material is an energy saver versus conventional systems. The savings can be more dramatic when compared with conventional sloped glazing systems.

Tensile membrane structure material specifications:

| PTFE Fiberglass Membrane | DuraSuntex DLT-PJ5800S | |

| Technology: | Muti layer PTFE (Teflon) coating |

| Base fabric | Fiberglass filaments EC6 |

| Surface: | Matte |

| Colour: | Eeige (Will transform into white colour after completed bleaching ) |

| Weight: | 1000gsm |

| Width: | 3-3.8meter |

| Thickness: | 0.6mm |

| Tensile strength: | 5800 (N/5cm) Warp / 5500 (N/5cm) Weft |

| Tearing strength: | 380 (N/5cm) Warp / 370 (N/5cm) Weft |

| Adhesion: | 60 (N/5cm) |

| Light transmission at 550nm: | 16-25% |

| Flame retardent: | B1/B-S1; d0 (DIN4102/EN 13501) |

| Welding methods: | Hot bar welding/FEP welding tape |

| Life span: | 25years |

| Suitable temperature: | -100°F to +450°F (-73°C to +232°C) |

Tensile membrane structure material features

- Extremely resistant to chemical and biological attack

- Extremely resistant to long-term exposure to weather and UV radiation

- For permanent structures

- High reflectance

- Self-cleaning

- Highest fire resistance

- Limited color possibilities

- Light transmission up to 20 %

- Life expectancy over 25 years

Tensile membrane structure material applications

- Museum of science

- International airport parking area, airport smart curb pavilion

- Stadium

- Railway station

- Central park