Description

Views: 1188

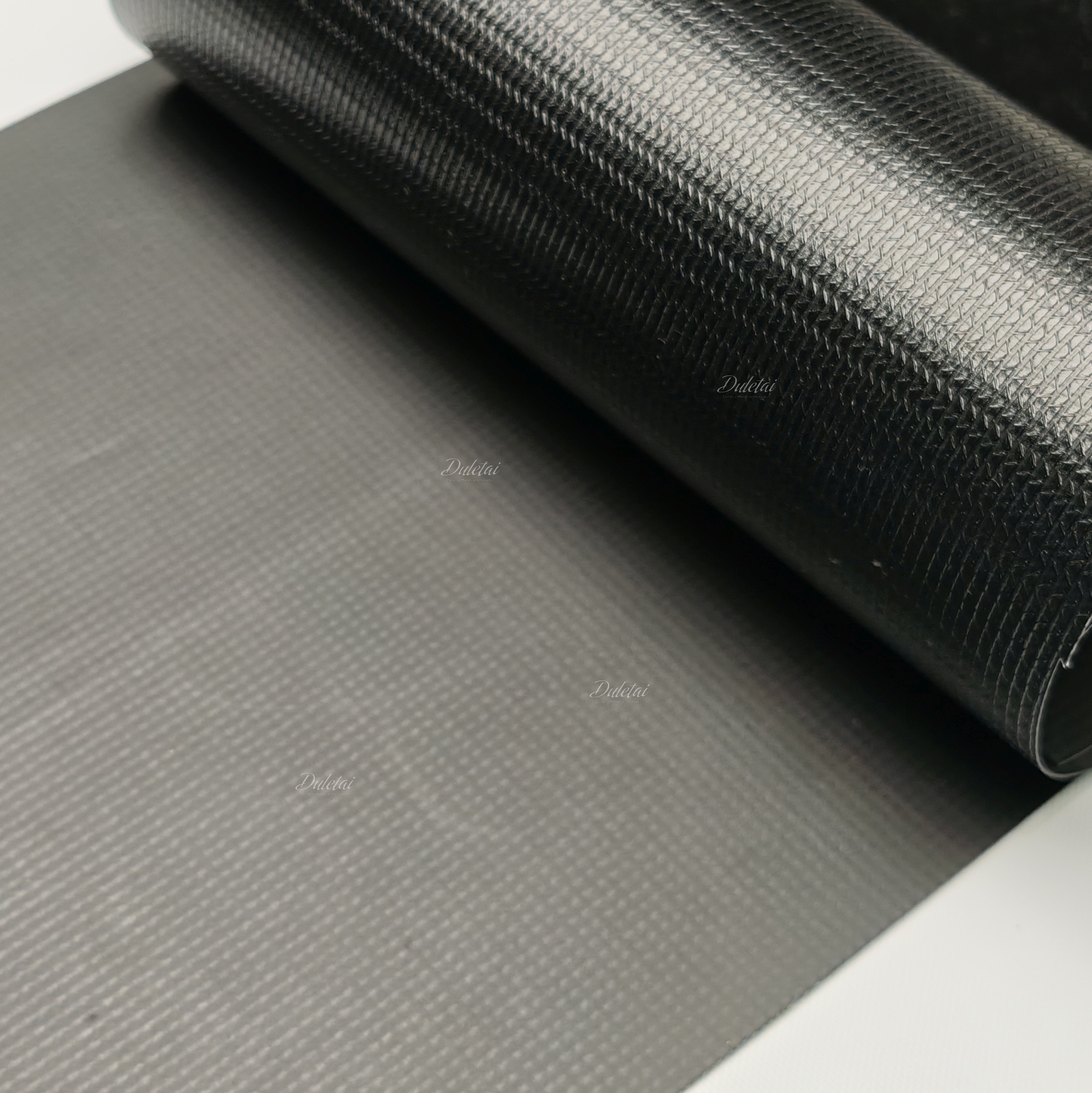

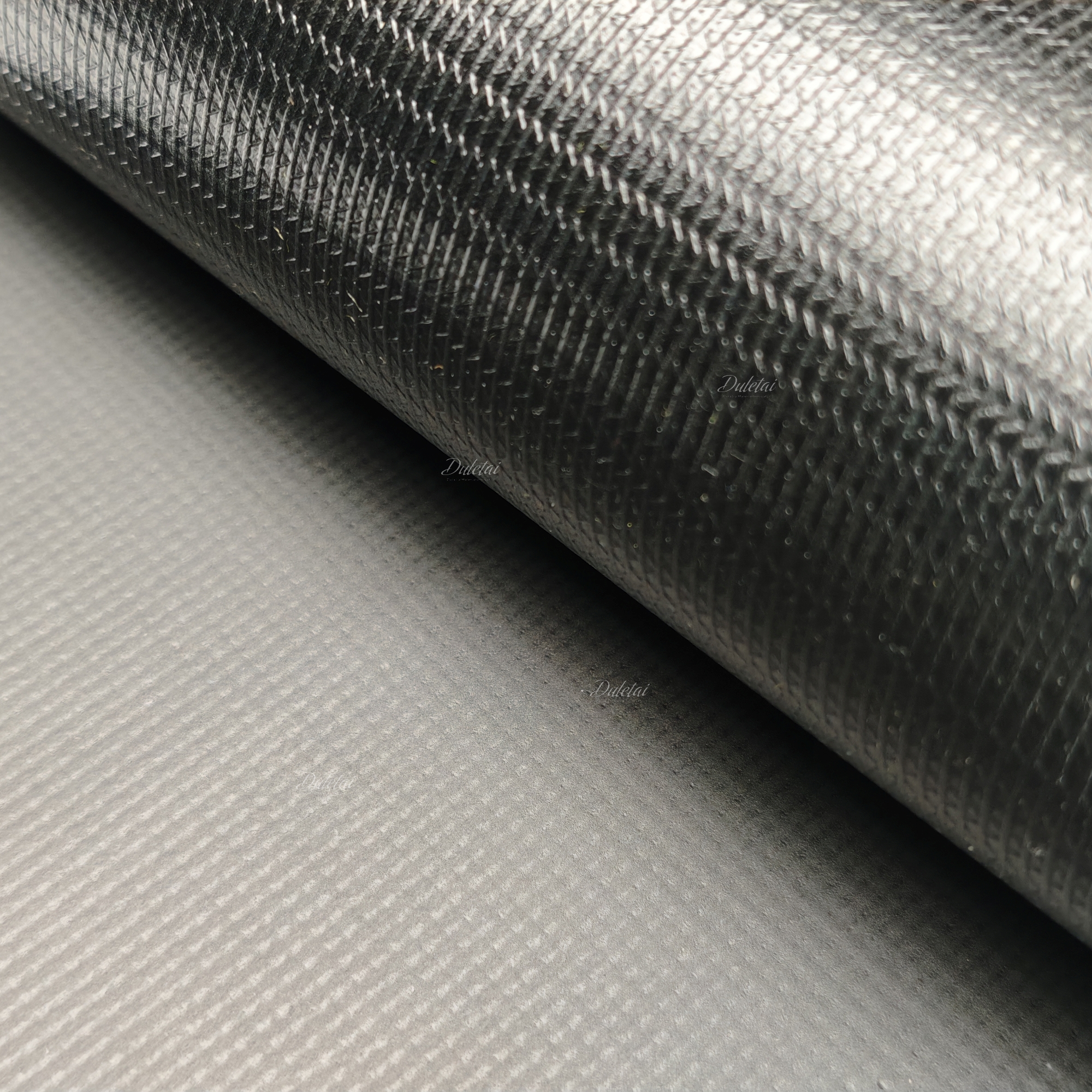

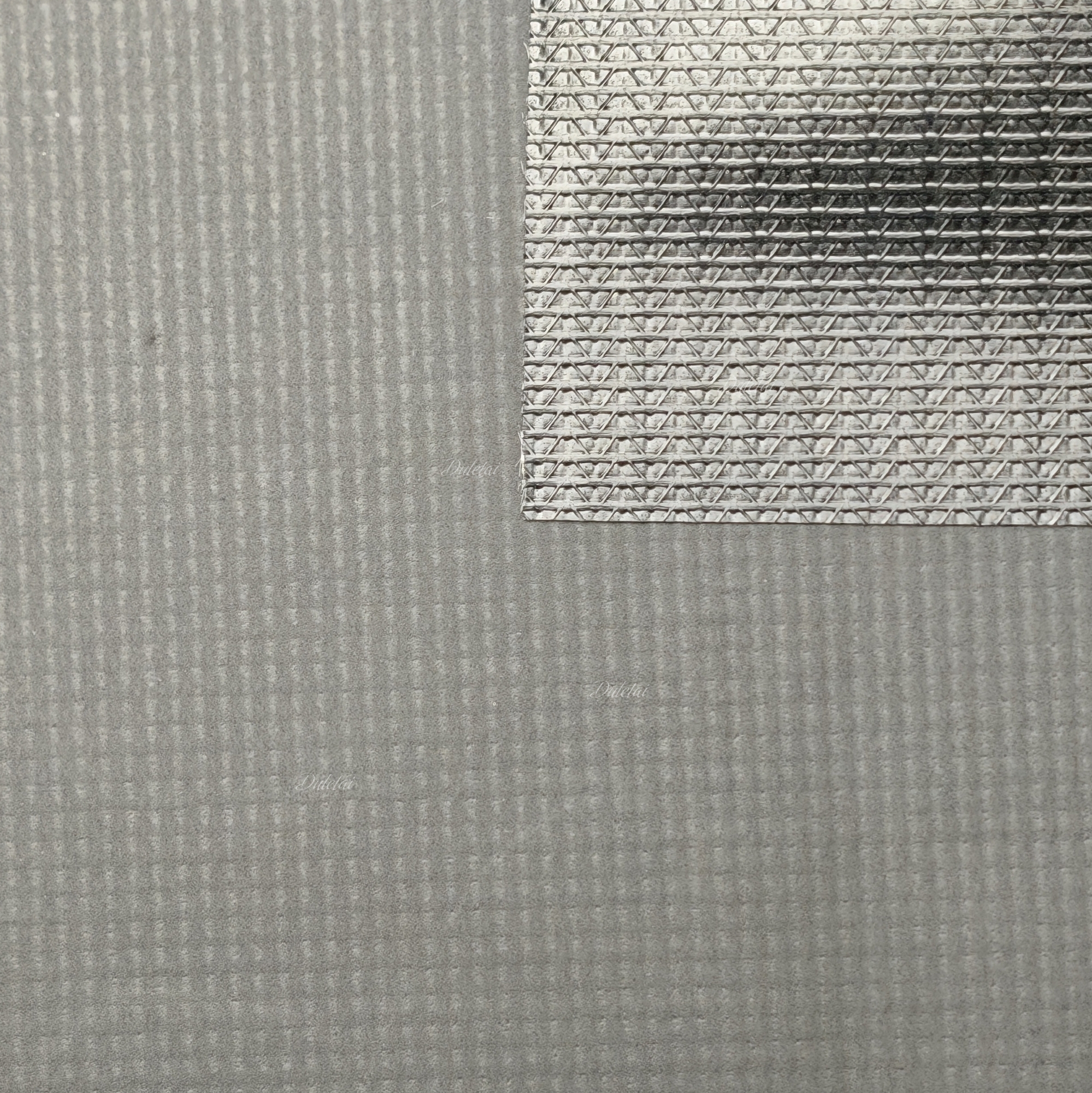

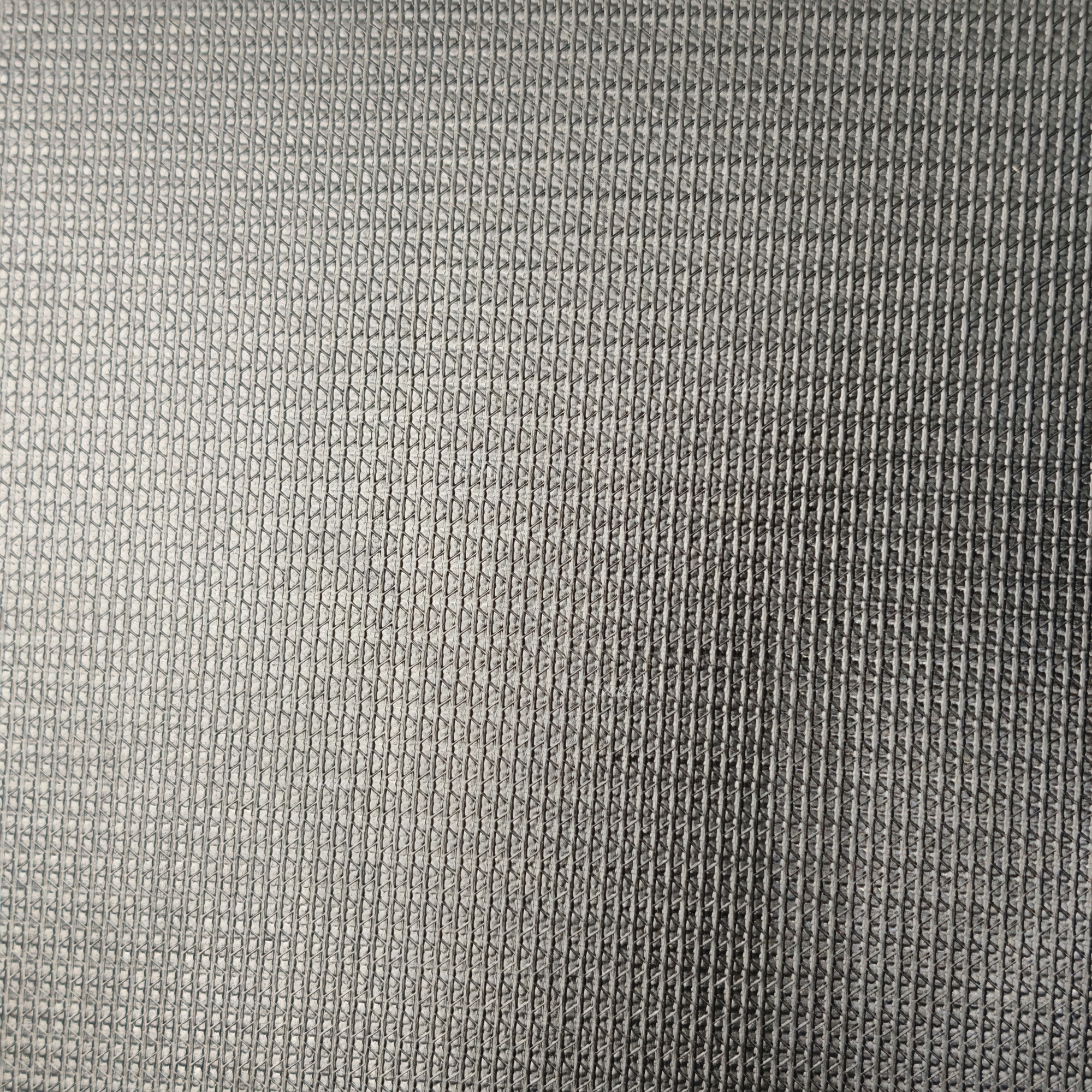

Flame retardant duct is engineered to mitigate fire hazards in high-risk environments, our certified FR PVC duct fabric delivers uncompromising safety for mining ventilation, chemical processing, and flammable material handling applications. The triple-layer composite structure—featuring a 1300D high-tenacity polyester core laminated between dual PVC films—ensures zero flame propagation while maintaining operational integrity under extreme conditions.

Technical Datasheet:

| Air duct material | DuraTarps DLT-5309 | |

| Structure: | PVC film+Polyester base fabric+PVC film |

| Base fabric: | 1300D |

| Width: | 1.02m-3.2m |

| Weight: | 600g(±10g)/sqm |

| Colour: | Black/Yellow/RAL1018 or customized |

| Flame retardant: | Self-extinguishing |

| Anti-static: | <200 megohm or 1×108Ω |

| Tearing strength: | 2200/1900(N/5cm) |

| Tensile strength: | 240/220(N/5cm) |

| Adhesive Strength | 80(N/5cm) |

| Suitable temperature: | -20° to +70° |

| Package: | Paper tube + Foam sheet +PE film |

| Meter per roll: | 30m-506m |

|

Flame retardant duct features:

|

|

| Download Digital Catalogue |

Applications:

Based on the search results, flame-retardant PVC materials demonstrate versatile applications across multiple high-risk industries due to their fire safety properties, durability, and chemical resistance. Key application domains include:

- Building & Construction

- Electrical Infrastructure

- Transportation & Mobility

- Industrial Safety & Critical Environments

- Emergency & Health Safety

Performance Comparison:

| Application | Key PVC Property | Safety Standard |

|---|---|---|

| Electrical Wiring | Low smoke emission | UL 94 V-0 |

| Mine Ventilation | Anti-static + Flame retardant | DIN4102 B1/B2/M1/M2 |

| Chemical Ducting | Acid resistance | NFPA 701 |

| Building Partitions | Toxicity reduction | CAN/ULC-S109-03 |