Description

Views: 6

PVC sun screen fabric from Duletai New Material represents a breakthrough in high-performance shading technology, specifically developed to meet the rigorous demands of modern architectural projects. While many standard fabrics on the market rely on low-grade PVC saturated with calcium fillers—leading to brittle textures, yellowing, and persistent chemical odors—our pvc sun screen fabric is engineered using a Refined Polymer Matrix. By coating a high-tenacity polyester core with high-purity, refined PVC, we ensure the material remains flexible, odorless, and exceptionally UV-stable. This dedication to material integrity provides a “Value Engineering” solution that guarantees long-term durability and a healthier indoor environment for both commercial and residential applications.

The technical core of our pvc sun screen fabric is its uncompromising dimensional stability. Through a sophisticated, calibrated thermal fixation process, we effectively “lock” the weave memory to eliminate internal tension. This specialized manufacturing step solves the industry’s most persistent challenges, such as edge-curl, “cupping,” and center-sagging, ensuring that every blind hangs perfectly flat even on large-scale vertical drops. Available in precise openness factors of 1%, 3%, and 5%, our fabric allows architects and contractors to strategically manage solar heat gain and glare while preserving a crisp, unobstructed view-through in high-end corporate offices, luxury hotels, and modern residential spaces.

To empower the growth of our wholesale and engineering partners, we have optimized our supply chain to offer a highly competitive 200-meter MOQ per specification. This flexibility allows you to access premium pvc sun screen fabric without the burden of heavy inventory costs or capital risk. We maintain an extensive, ready-to-ship inventory in a refined palette of architectural colors and offer the strategic benefit of mixed-load consolidation, allowing you to combine different openness factors and widths in a single shipment. At Duletai, we do more than manufacture fabric; we provide the technical consistency and logistical responsiveness that secure your project’s success and enhance your bottom line.

Technical Datasheet:

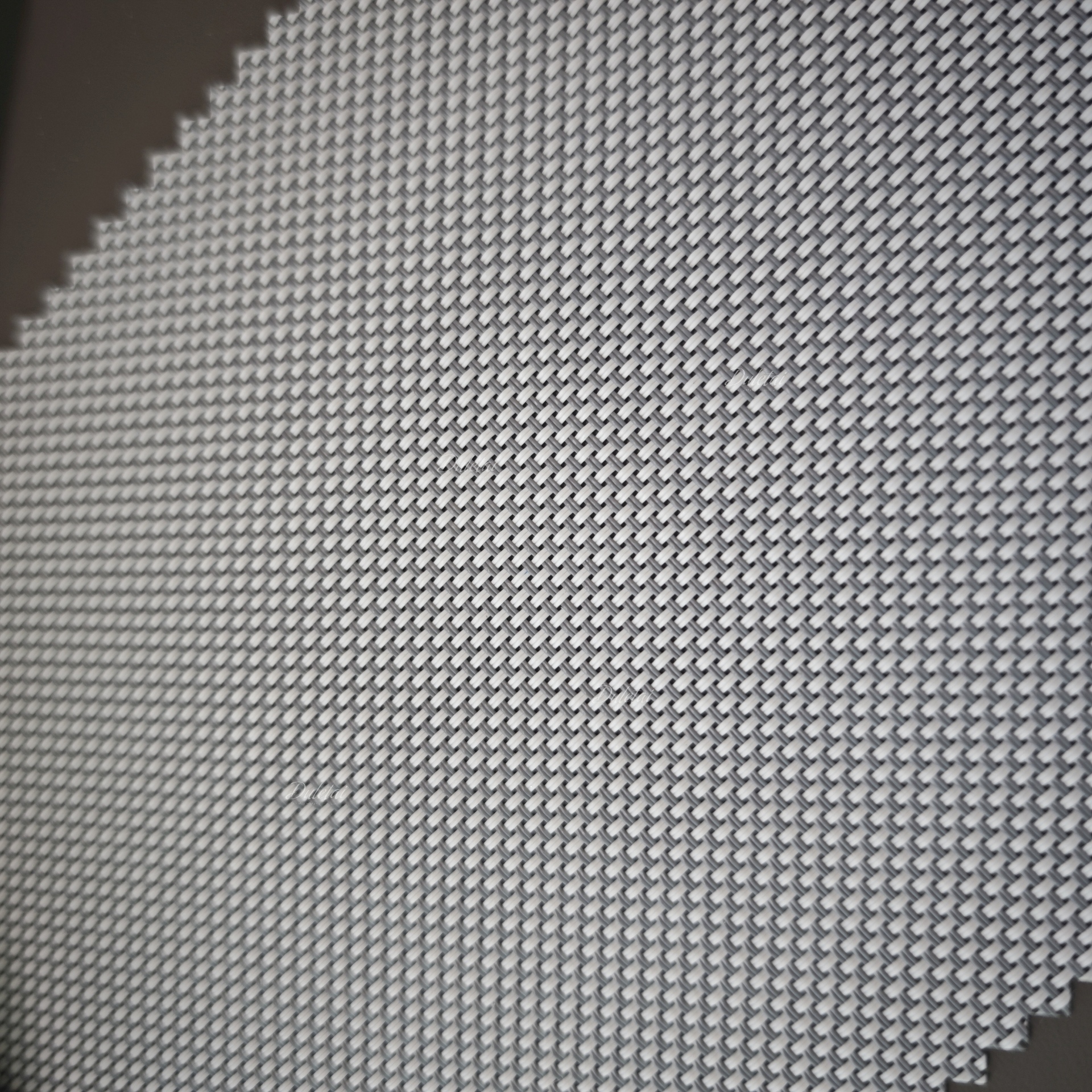

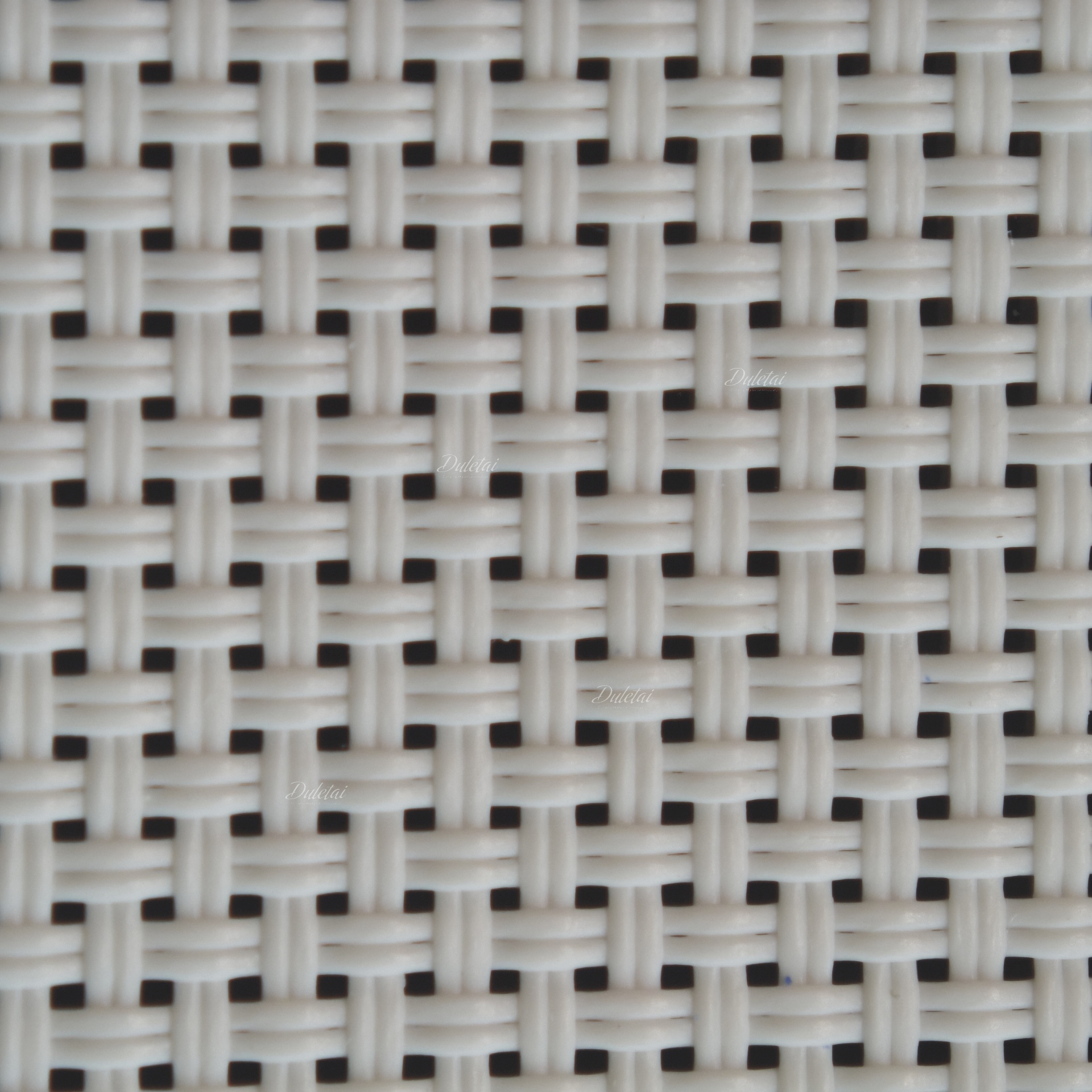

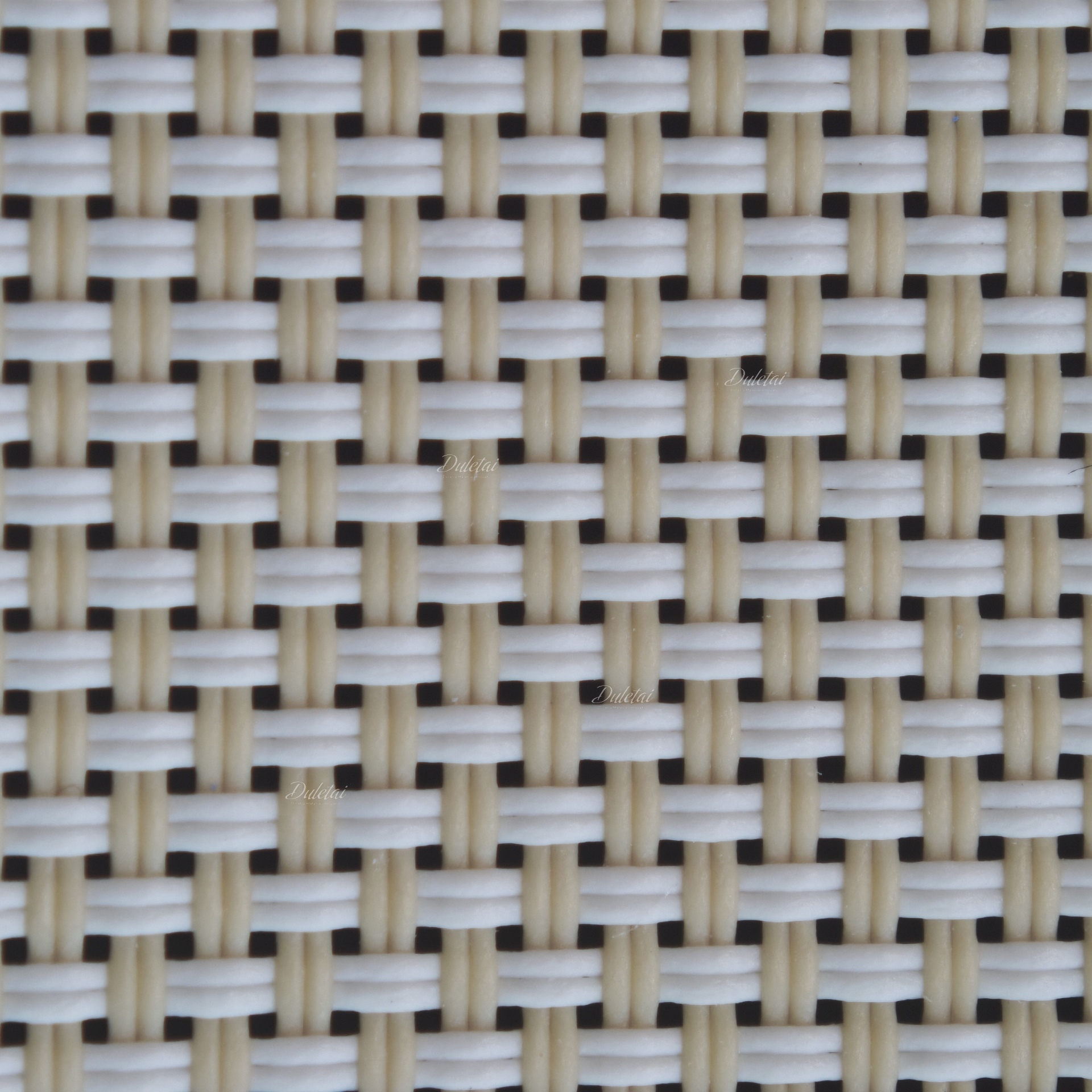

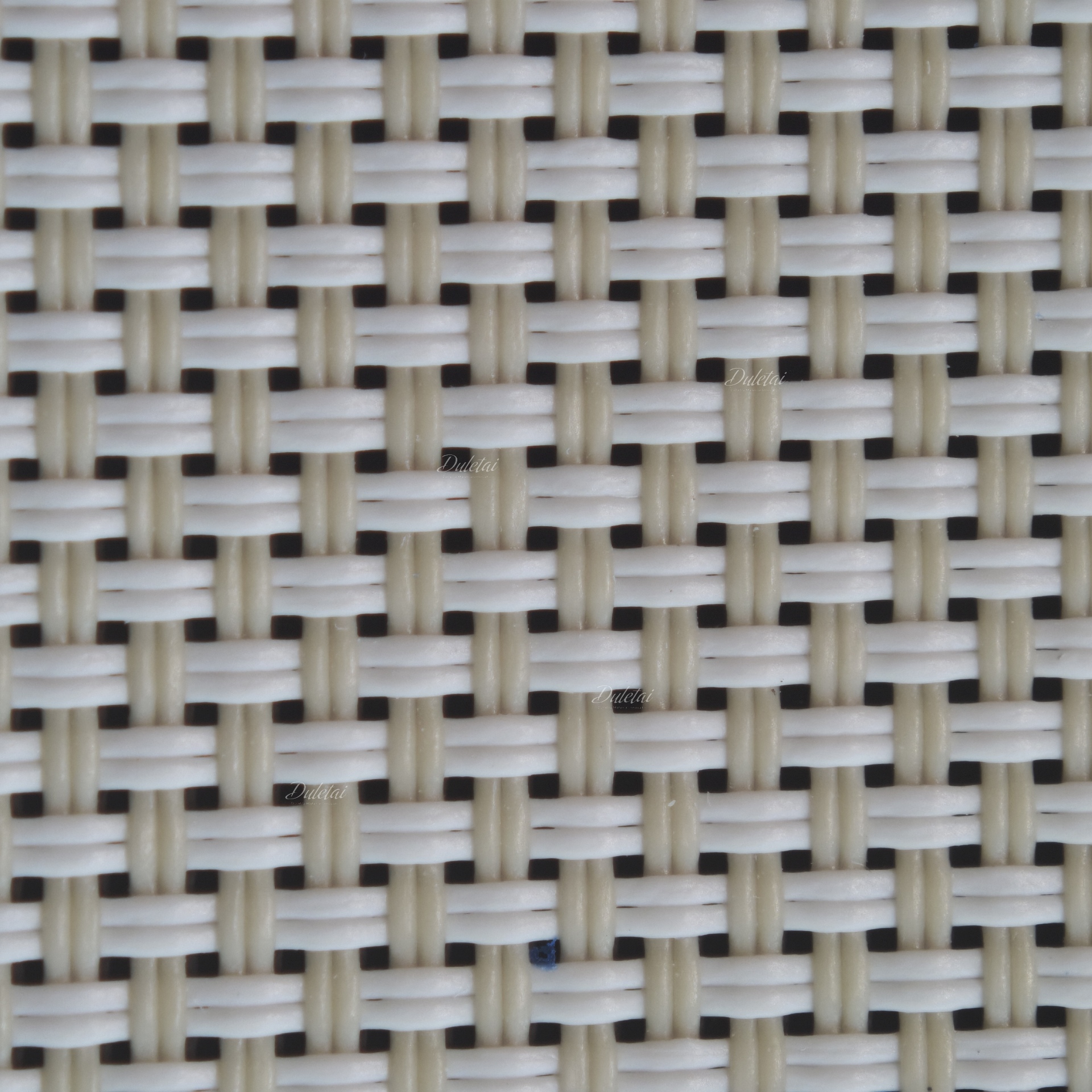

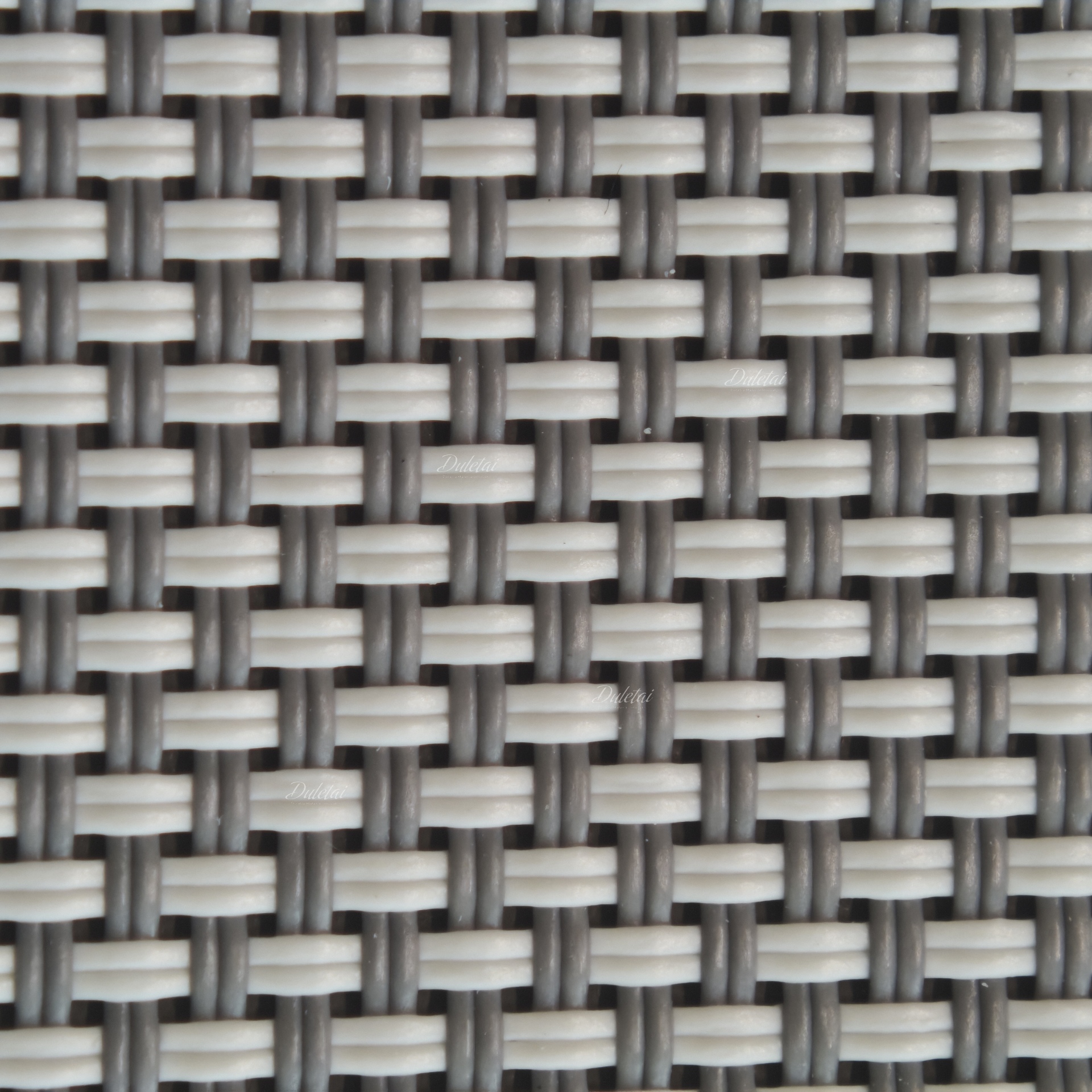

| Sunscreen Fabric | DLT-SL5400 | |

| Composition: | 30% Polyester + 70% PVC |

| Yarn Spec: | 1800D 36X34/inch |

| Pattern: | Plain weave 2X2 |

| 2Width: | 2.0 / 2.5 / 3.0meters |

| Weight: | 470gsm±5% |

| Thickness: | 0.65±5% |

| Roll length: | 35meters |

| Openess: | 5% |

| Colour fastness: | 8 |

| Fire Resistance: | B2 |

| UV Blockage: | UPF 50+ |

| MOQ: | 200meters |

| Packing: | Polybags +outside hard paper tube |

|

|

|

|

| DLT-SL5401 White |

DLT-SL5402 Yellow+White |

DLT-SL5403 Beige+White |

DLT-SL5404 Grey+White |

Testing Reports:

Features:

-

Refined PVC Formulation: Unlike standard fabrics that use heavy mineral fillers (calcium powder), our “Refined Polymer Matrix” ensures the material remains flexible, odorless, and resistant to UV-degradation over time.

-

Superior Dimensional Stability: Utilizing a calibrated thermal fixation process, we lock the weave in place. This prevents common industry failures such as edge-curl, center-sagging, or “cupping,” even on long vertical drops.

-

Precision Openness Factors: Available in 1%, 3%, and 5% openness, allowing for “Value Engineering” where light harvesting, glare reduction, and visual transparency can be tailored to specific building elevations.

-

High-Tenacity Polyester Core: The internal core provides exceptional tensile and tear strength, ensuring the fabric handles the mechanical tension of automated and manual roller systems without stretching.

-

Climate & Health Safety: Our low-VOC, odorless formulation is engineered for sensitive indoor environments. It is UV-stabilized to prevent yellowing and is available with flame-retardant (NFPA 701/B1) and anti-microbial treatments.

-

Logistical Flexibility: We support your supply chain with ready-to-ship inventory and a low 200m MOQ, allowing for mixed-spec container consolidation to optimize your landed costs.

Roller Shade Screen Applications:

-

Commercial Offices & Workspaces: Eliminates screen glare and reduces solar heat gain, significantly lowering HVAC costs while maintaining a productive, naturally lit environment.

-

Hospitality & High-End Hotels: Provides a unified, refined aesthetic for building facades while offering guests customizable privacy and thermal comfort.

-

Healthcare & Medical Facilities: Ideal for clinics and hospitals where odorless, easy-to-sanitize, and flame-retardant materials are non-negotiable requirements for patient safety.

-

Educational Institutions: Durable enough for high-traffic use in classrooms and libraries, providing a comfortable visual atmosphere that supports learning and focus.

-

Public Infrastructure: Suitable for airports, museums, and transport hubs where large-scale shading systems must operate continuously with minimal maintenance.

-

Residential Luxury: Protects premium furniture, artwork, and flooring from UV damage while preserving the exterior view and enhancing the interior design.