Description

Views: 315

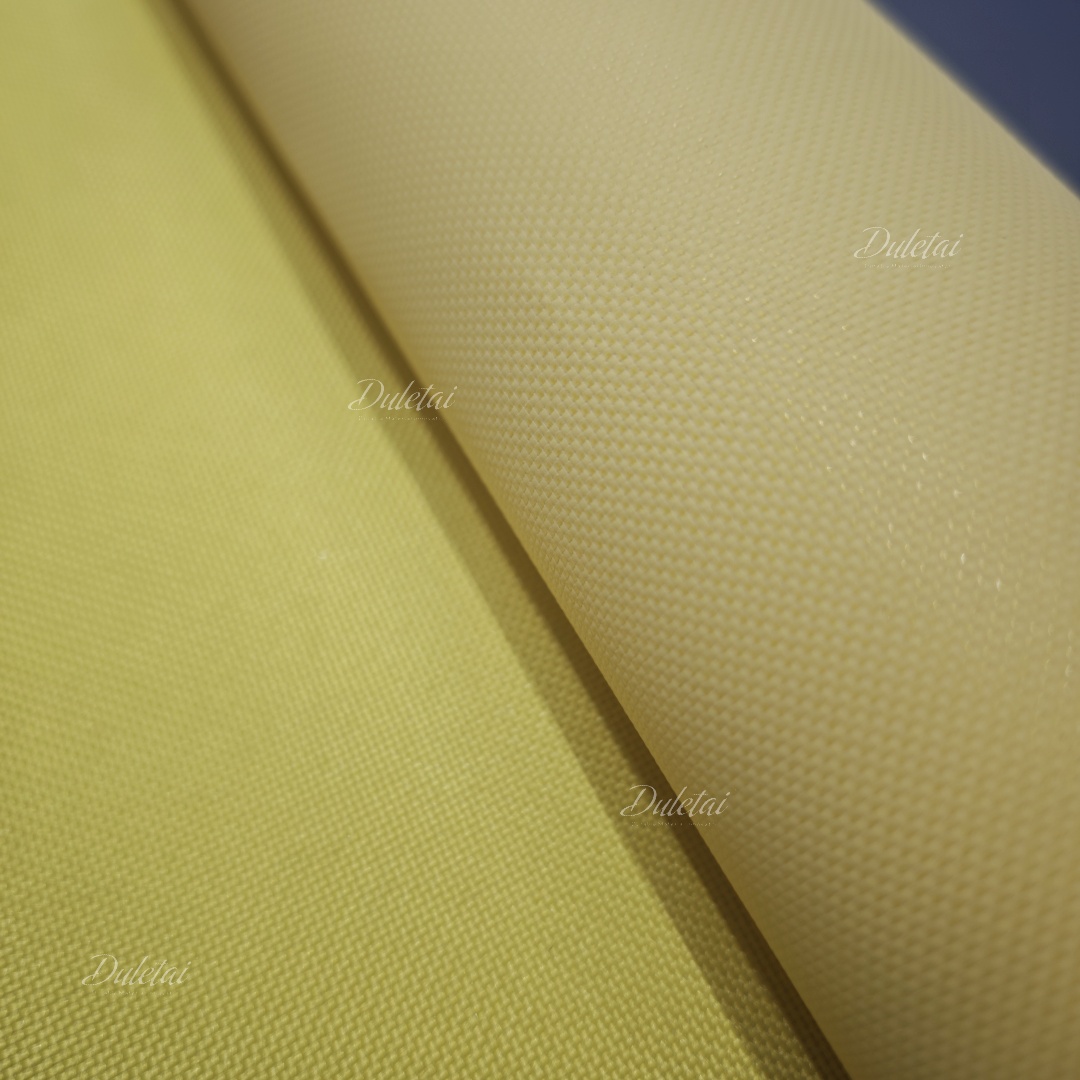

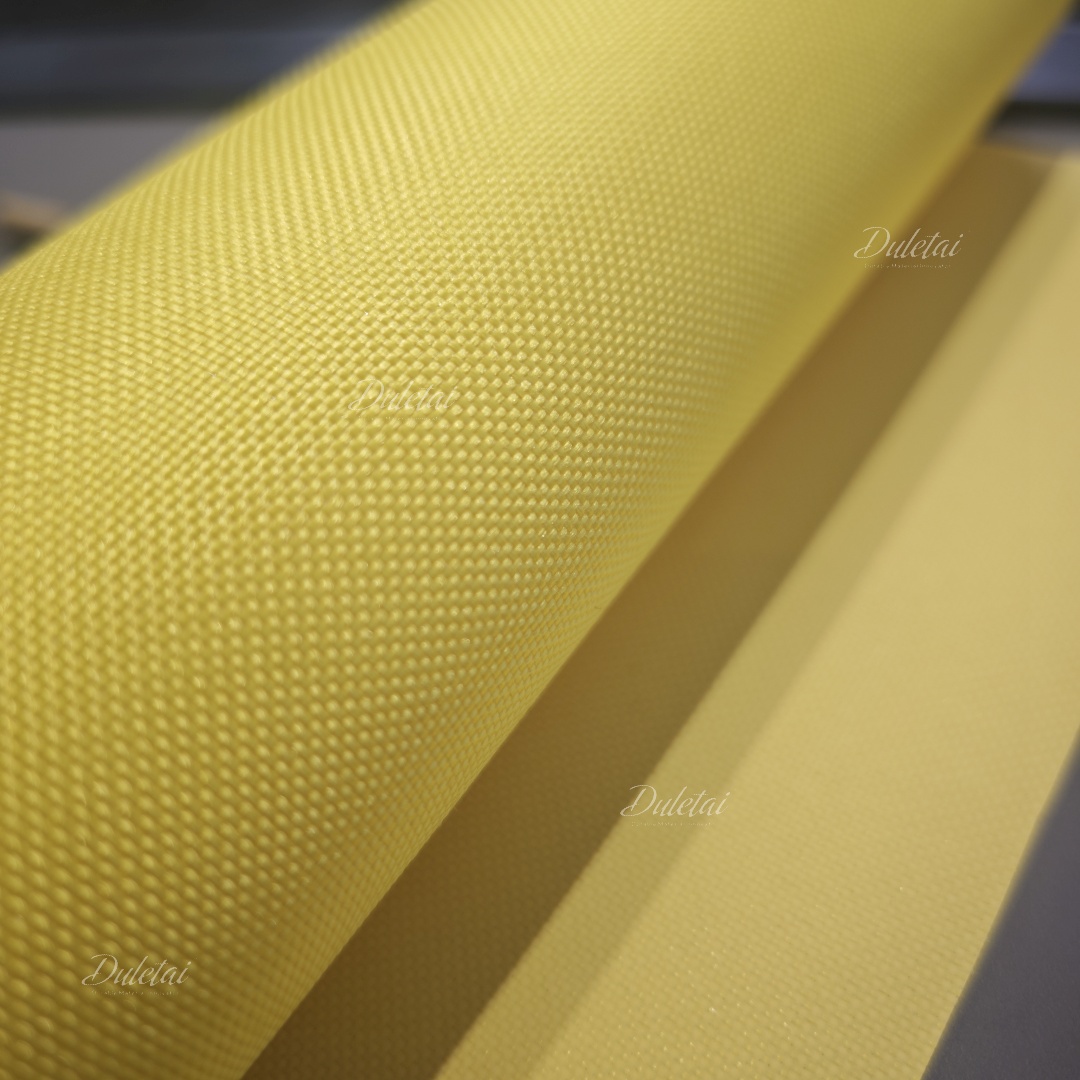

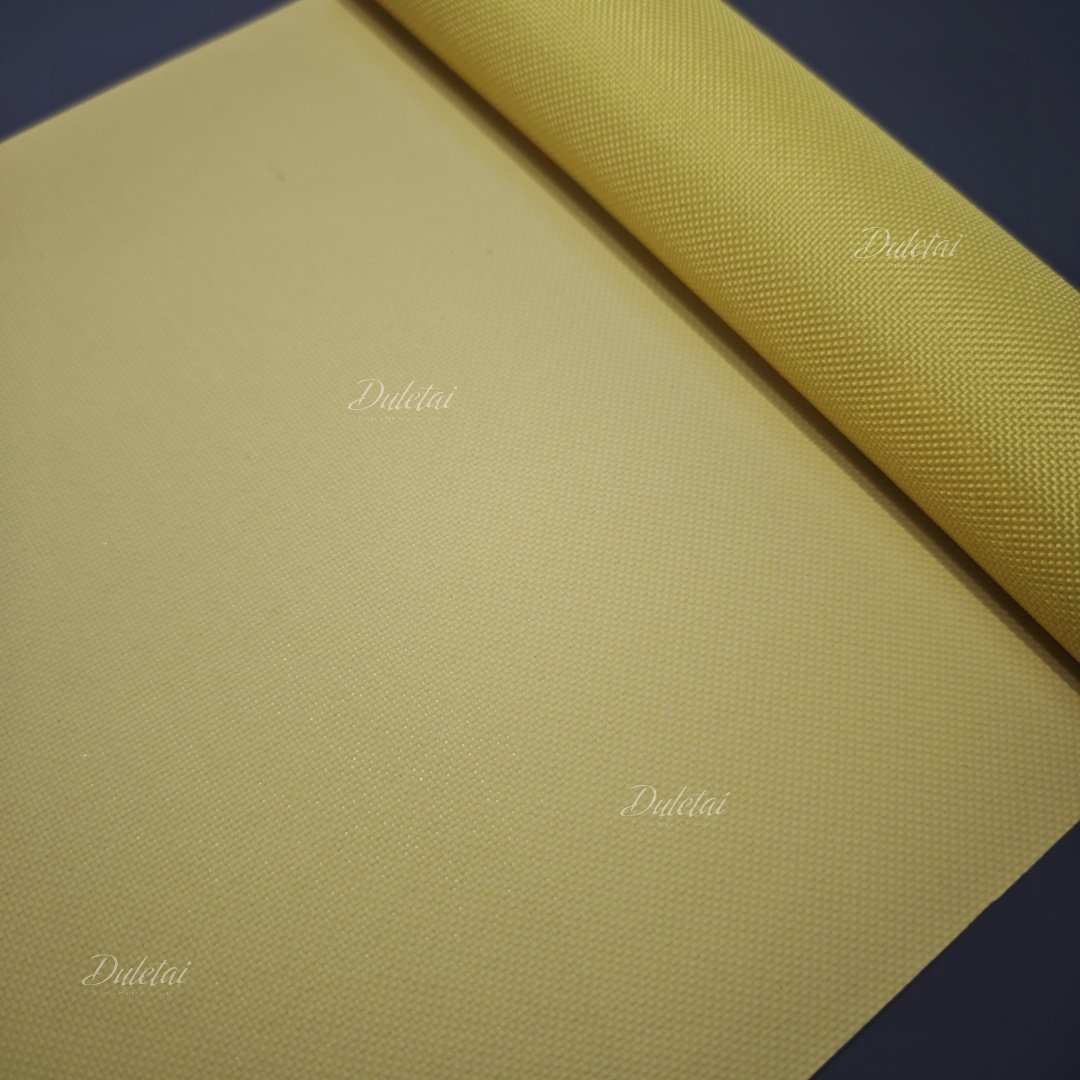

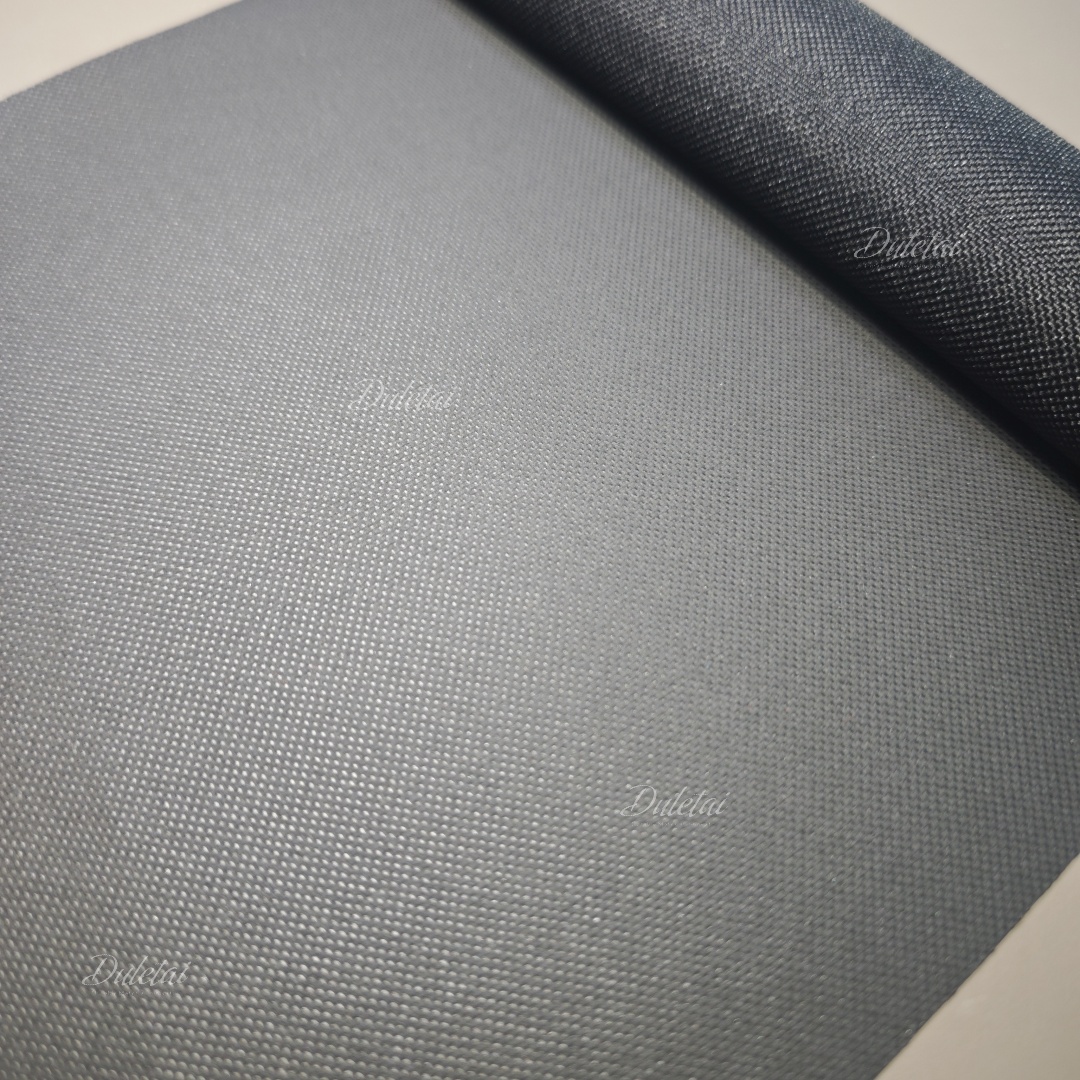

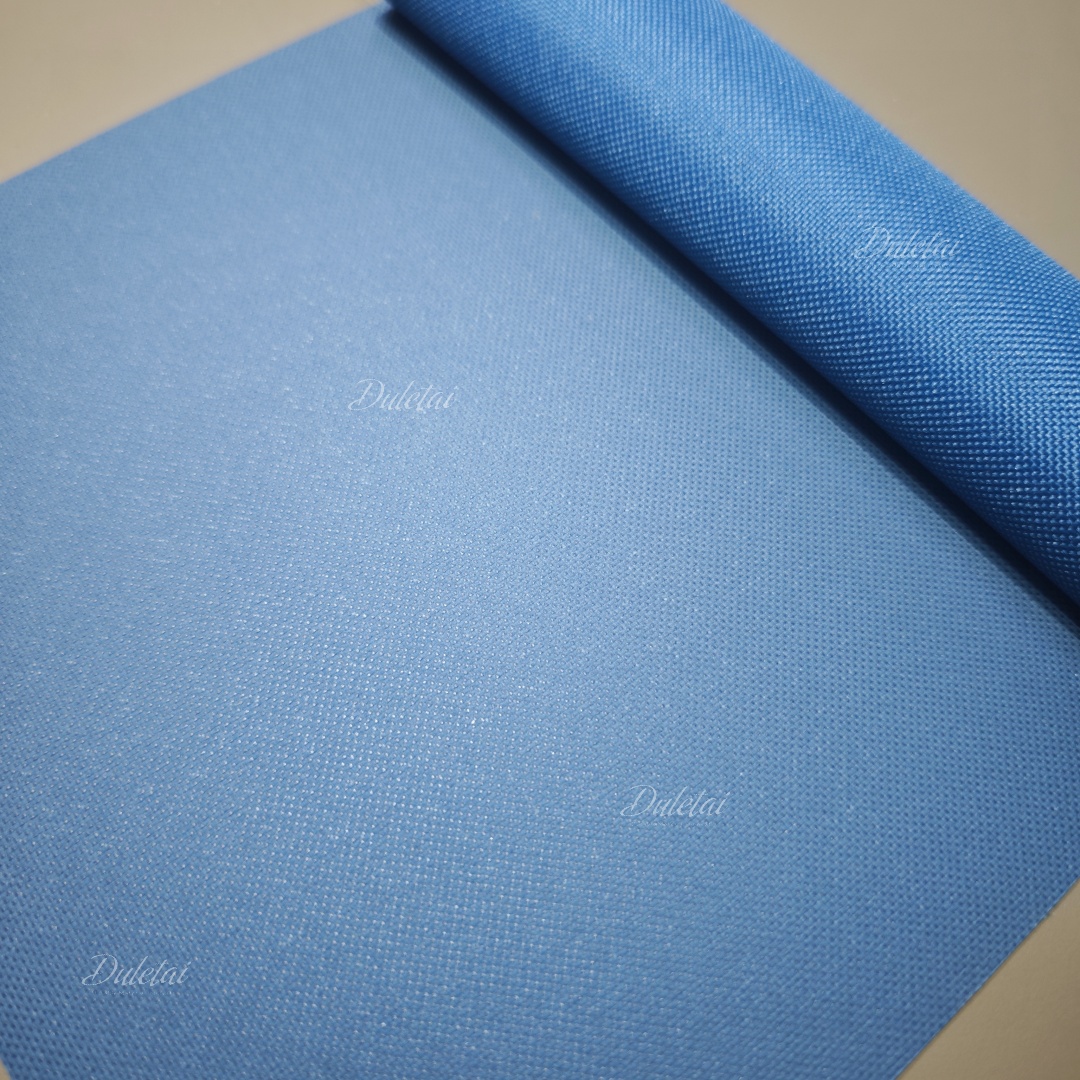

Air duct fabric is specifically designed for airflow control, durability, and safety. The polyester base fabric provides high tensile strength, dimensional stability, and resistance to deformation, allowing the duct to maintain a consistent shape during long-term operation. The PU coating precisely controls air permeability, improves air tightness where required, and adds water resistance, surface strength, and ease of cleaning.

Yellow | RAL1021 Yellow | RAL1021 |

Red | RAL3020 Red | RAL3020 |

Black | RAL9017 Black | RAL9017 |

Blue | RAL5005 Blue | RAL5005 |

Grey | RAL7040 Grey | RAL7040 |

Compared with PVC fabric air duct materials, Polyester fabric remains flexible under repeated folding, installation, and washing. It also provides better tear resistance and fatigue performance, especially in large-span systems or applications requiring frequent maintenance. In terms of fire safety, this type of textile can achieve stable and reliable flame retardant performance in compliance with EN or NFPA standards, without relying on high plasticizer content, resulting in more consistent aging behavior. In low-temperature or high-humidity environments such as cold storage, food processing, and logistics facilities. As a direct manufacturer, our material performance is controlled from the beginning of the production process. High-tenacity polyester yarns are carefully selected, followed by controlled weaving process to achieve the required strength, fabric density, and weight. The fabric then undergoes heat setting and dimensional stabilization before single-side or double-side PU coating is applied to meet specific airflow, water resistance, and durability requirements.Functional finishes such as flame retardant, anti-mildew, and anti-static treatments are added according to project needs, followed by strict inspection of fabric weight, width, air control, and mechanical properties. This integrated manufacturing process allows full customization of fabric weight, color, yarn specification, fabric width, and functional performance, enabling precise matching with different airflow designs and fabric air duct system requirements. For fabric air duct system manufacturers and HVAC integrators, Our material provides a reliable, durable, and technically balanced material solution. If you are looking for a customizable material, we are ready to support your project with samples, technical data, and material expertise.

Air Duct Fabric Technical Datasheet:

| AIR DUCT FABRIC | DURAOXFORD DLT-3701 | |

| Structure: | Signle side PU coated polyester fabric |

| Yarn type: | 600D |

| Width: | 1.5m-2.5m |

| Weight: | 230g(±10g)/sqm |

| Thickness: | 0.3mm |

| Colour: | Customize |

| Tearing strength: | 240(N/5cm) |

| Tensile strength: | 2500(N/5cm) |

| Suitable temperature: | -40 °C to +110 °C |

| Water proof: | Water pressure ≥1500 mm |

| Flame retardant: | DIN 4102 B1 |

| Customization: | REACH compliant |

| Package: | Paper tube 76 mm (3″) paper core +PE Bag |

| Meter per roll: | 30m-500m |

Features:

|

|

|

|

|

|

|

|

|

|

|

|

Fabric Air Ducting (Textile Duct Systems)

|

Industrial HVAC & Ventilation

|

Commercial HVAC Applications

|

Hygienic & Controlled HVAC Environments

|

HVAC Systems in Cold & Humid Areas

|

|