Description

Views: 550

Flame retardant vinyl film is a specialized polyvinyl chloride material enhanced with chemical additives to suppress combustion, reduce smoke toxicity, and minimize fire propagation risks. Widely used in construction, electronics, automotive, and packaging industries, this engineered film achieves its critical safety properties through multiple mechanisms:

- Halogen-based flame suppression: Chlorinated paraffin (e.g., Chlorinated Paraffin-70) and antimony trioxide (Sb₂O₃) additives interrupt combustion chain reactions by releasing flame-inhibiting gases when exposed to heat.

- Char barrier formation: During fire exposure, additives like aluminum hydroxide (Al(OH)₃) and modified magnesium hydroxide (MH) decompose endothermically, absorbing heat and forming an insulating char layer that blocks oxygen diffusion.

- Toxicity control: Advanced formulations reduce toxic fume generation (e.g., hydrogen chloride gas) by up to 50% compared to standard PVC, while maintaining low smoke density for clearer evacuation pathways.

Flame retardant vinyl (PVC) film chieves critical safety certifications including NFPA701,UL94, EN13501, and DIN 4102 through optimized formulations—for instance, combining Sb₂O₃ with polyester plasticizers elevates LOI to 32% (though often compromising light transmission). Market trends prioritize non-halogen alternatives like zinc borate and ammonium polyphosphate (APP) for enhanced sustainability, alongside advanced processes like resin transfer molding (RTM) for manufacturing naval or semiconductor-grade components—all driven by a projected CAGR growth through 2033, balancing performance, compliance, and eco-efficiency.

Technical Datasheet:

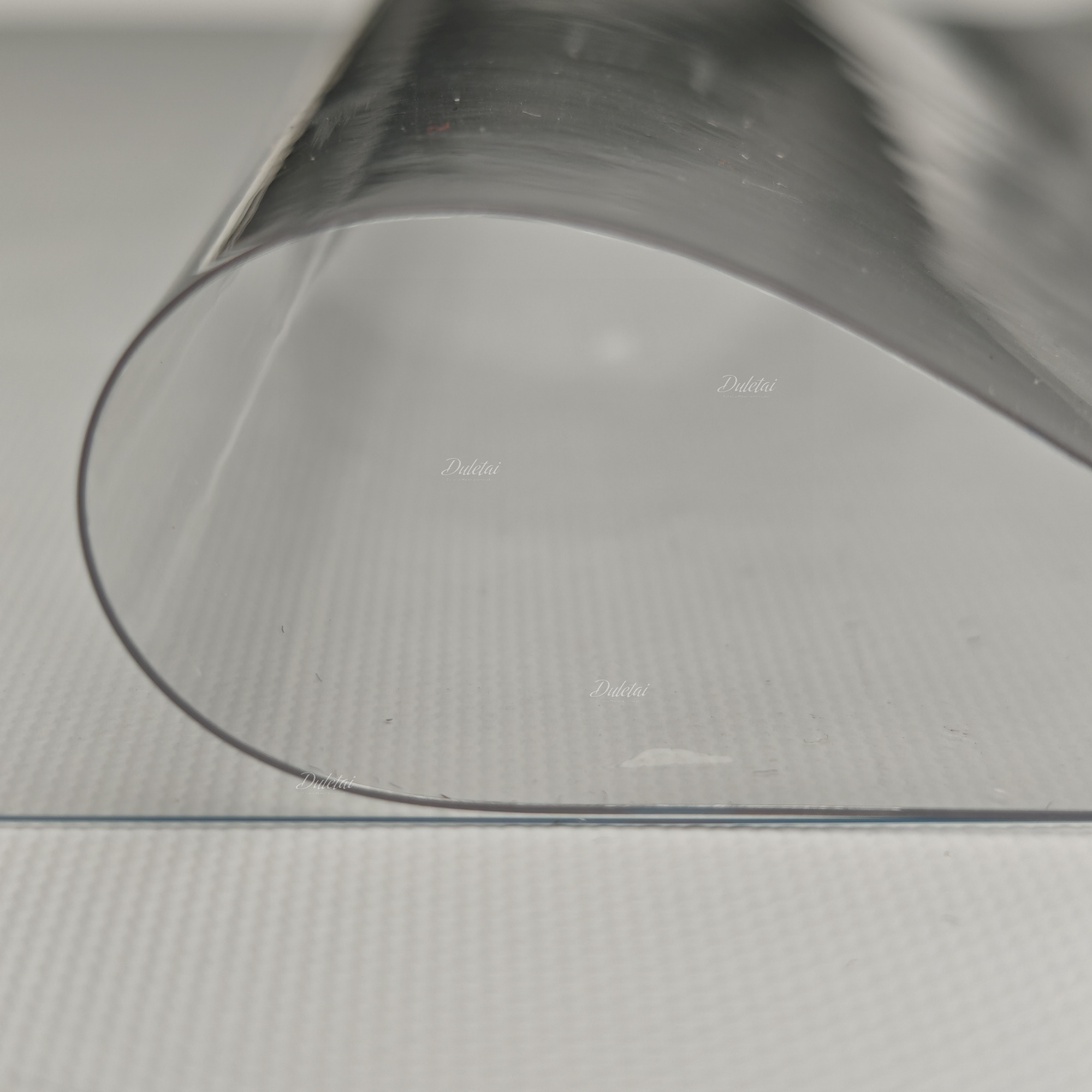

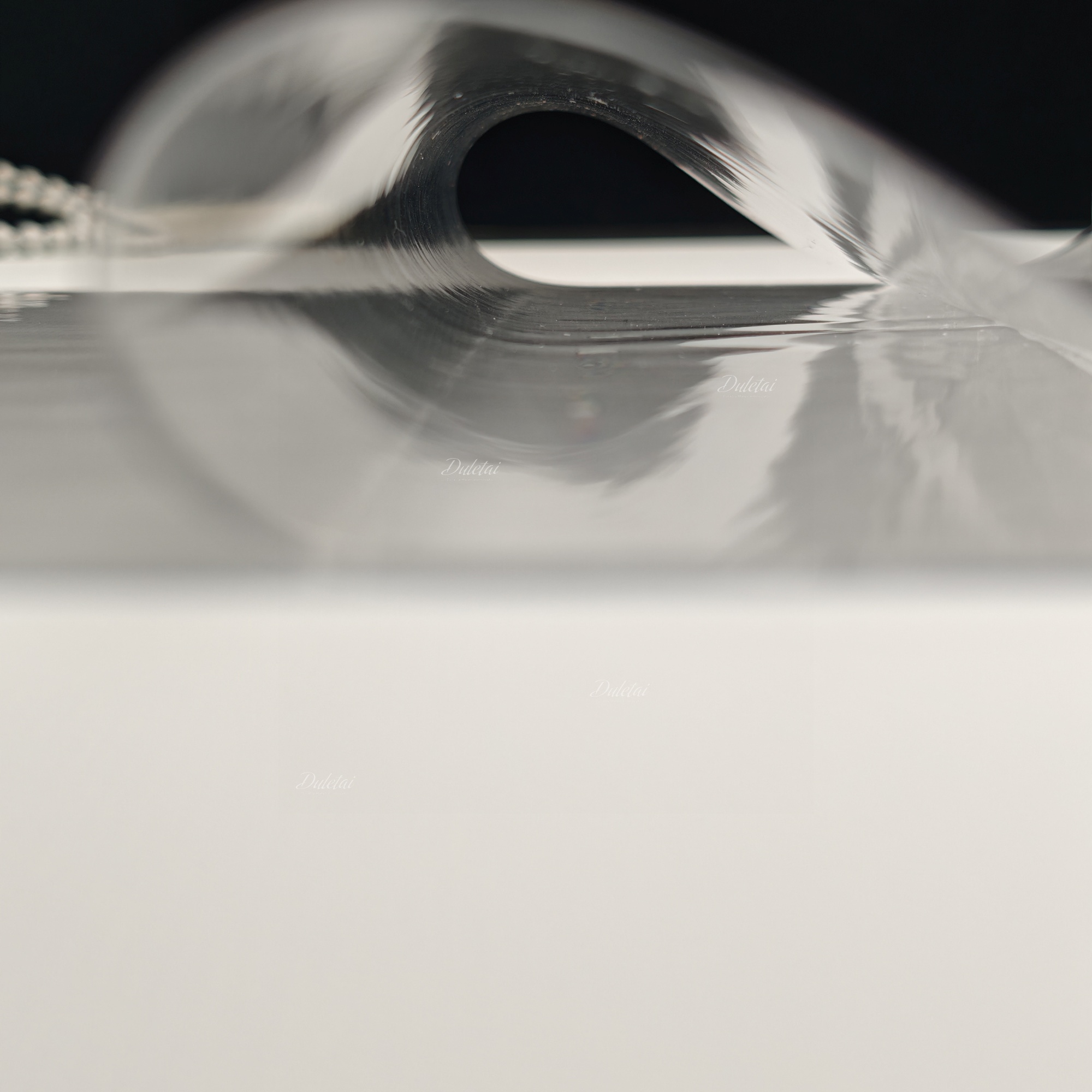

| Super clear PVC film | DuraTarps DLT-7003 |

|

| Technology: | Calendering+Lamination |

| Feature: | Water quench |

| Hardness: | 20-60 PHR According to customer’s requirements |

| UV resistetant | 3.5 ASTM G154-06 Standard |

| Transparency: | Super clear / Crystal clear |

| Thickness: | 0.3mm |

| Max width: | 2.4meters |

| Vicat softening point: | 75°C |

| Packing: | PE foam or kraft paper with clear film or color film; |

| Certification: | Reach/RoHS; Anti UV; Anti Cold; Anti Static; Fire Retardent |

| ITEM | PHR | 30PHR↓ | 31~40 | 41~50 | 51~60 | Test method |

|---|---|---|---|---|---|---|

| Tensile strength (kg/cm²) |

MD | ≧250 | ≧230 | ≧210 | ≧180 | ASTM D-882 |

| CD | ≧230 | ≧210 | ≧190 | ≧170 | ||

| Elongation (%) |

MD | ≧170 | ≧200 | ≧220 | ≧260 | ASTM D-882 |

| CD | ≧180 | ≧220 | ≧240 | ≧280 | ||

| Tear strength (kg/mm) |

MD | ≧9 | ≧7 | ≧6 | ≧5 | ASTM D-882 |

| CD | ≧9 | ≧7 | ≧6 | ≧5 | ||

| ITEM | Thickness (mm) / PHR | 30PHR↓ | 31~40 | 41~50 | 51~60 | Test method |

| Dimensional stability (-%) |

0.09m/m↓ | ≦5 | ≦7 | ≦9 | ≦9 | ASTM D-882 |

| 0.091-0.152 | ≦4 | ≦6 | ≦7 | ≦8 | ||

| 0.153-0.254 | ≦3 | ≦5 | ≦6 | ≦7 | ||

| 0.255-0.50 | ≦3 | ≦4 | ≦4 | ≦5 |

Flame Retardant Vinyl Applications

- Vacuum forming

- Medicine package

- Helmit

- Folding box

- Food packing

- Table cloth

- Pergola side curtain

- Tent side