Views: 956

Flame retardant PVC tarpaulin is a special type of polyester fabric combined with PVC and fire-resistant additives. Unlike regular tarps, it slows down or stops fire from spreading, making it essential for places where fire safety is critical.When fire touches it:

✅ Slows down flames

✅ Stops burning when fire source is removed

✅ Protects what’s underneath

What’s Inside?

Flame retardant PVC tarpaulin is manufactured through a specialized process that involves:

- Base Material: High-strength polyester canvas that provides structural integrity

- PVC: Coated or laminated polyvinyl chloride (PVC) layer

- Flame Retardant Additives: Specific chemical compounds added during manufacturing

- Additional Additives: Accelerators, mildew inhibitors, anti-aging agents, and anti-static agents

| Component | What It Does |

|---|---|

| Polyester Fabric Base | Makes it strong and tear-proof |

| PVC Plastic | Makes it waterproof & flexible |

| Fire-Stop Chemicals | Prevents flames from spreading |

| Extra Protectors | Fights UV rays, mold & aging |

| Core Technology and Materials | ||

| Antimony Trioxide (Sb₂O₃) | Smoke Reduction | Dripping Control |

| Added to the PVC formulation to boost flame suppression. | Reduce toxic fume generation by up to 50% during fire exposure. | Reduced calcium carbonate formulation minimizes melt-dripping behavior. |

| Works with halogen compounds to form protective char barriers during combustion. | Minimize release of hazardous chemicals (including HCl gas). | Eliminates secondary fire hazards from falling molten material. |

| Significantly increases oxygen index (LOI) to achieve self-extinguishing properties. | Create clearer evacuation pathways in emergency scenarios. | Maintains fabric structural integrity at high temperatures. |

️ Where it’s used?

| Industry | Applications |

|---|---|

| Transport | Truck/train covers, cargo protection |

| Construction | Temporary shelters, scaffolding covers, debris containment |

| Events | Festival tents, stage backdrops, exhibition dividers |

| Storage | Warehouse covers, machinery protection |

| Public Spaces | Hospital barriers, school safety installations |

Global Safety Standards

| Standard | Country/Region | Key Classifications |

| Euroclasses (EN13501-1) | European Union | A1-F, s1-s3, d0-d2 |

| M Classification | France | M0-M4 |

| B Classification (DIN4102) | Germany | B1-B3 |

| NFPA 701 | United States | Test Method 1 & 2 |

| AS/NZS 1530 | Australia/New Zealand | Part 1-4 |

| Key Tests: How fast fire spreads / How long it keeps burning / How much smoke it makes | ||

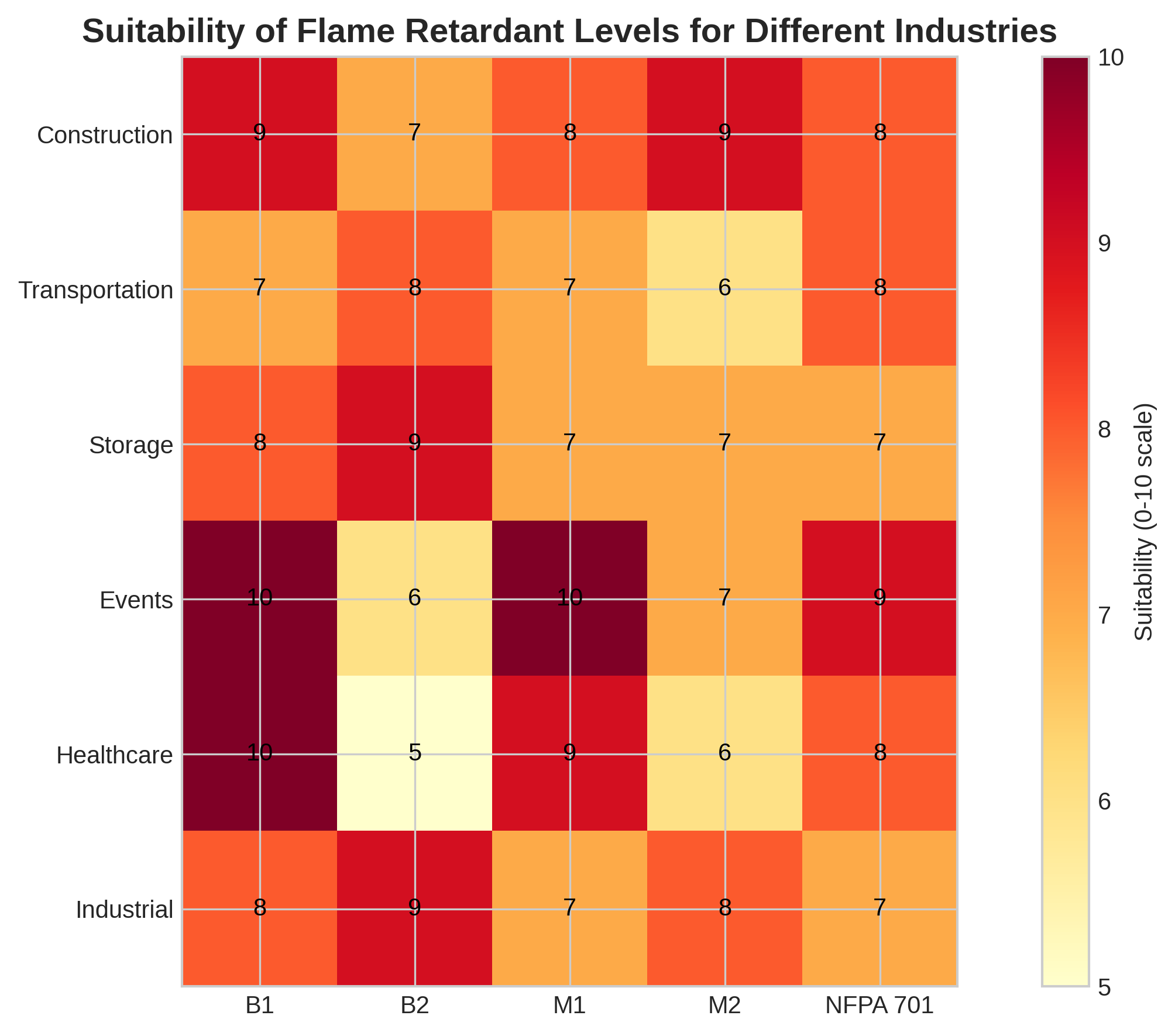

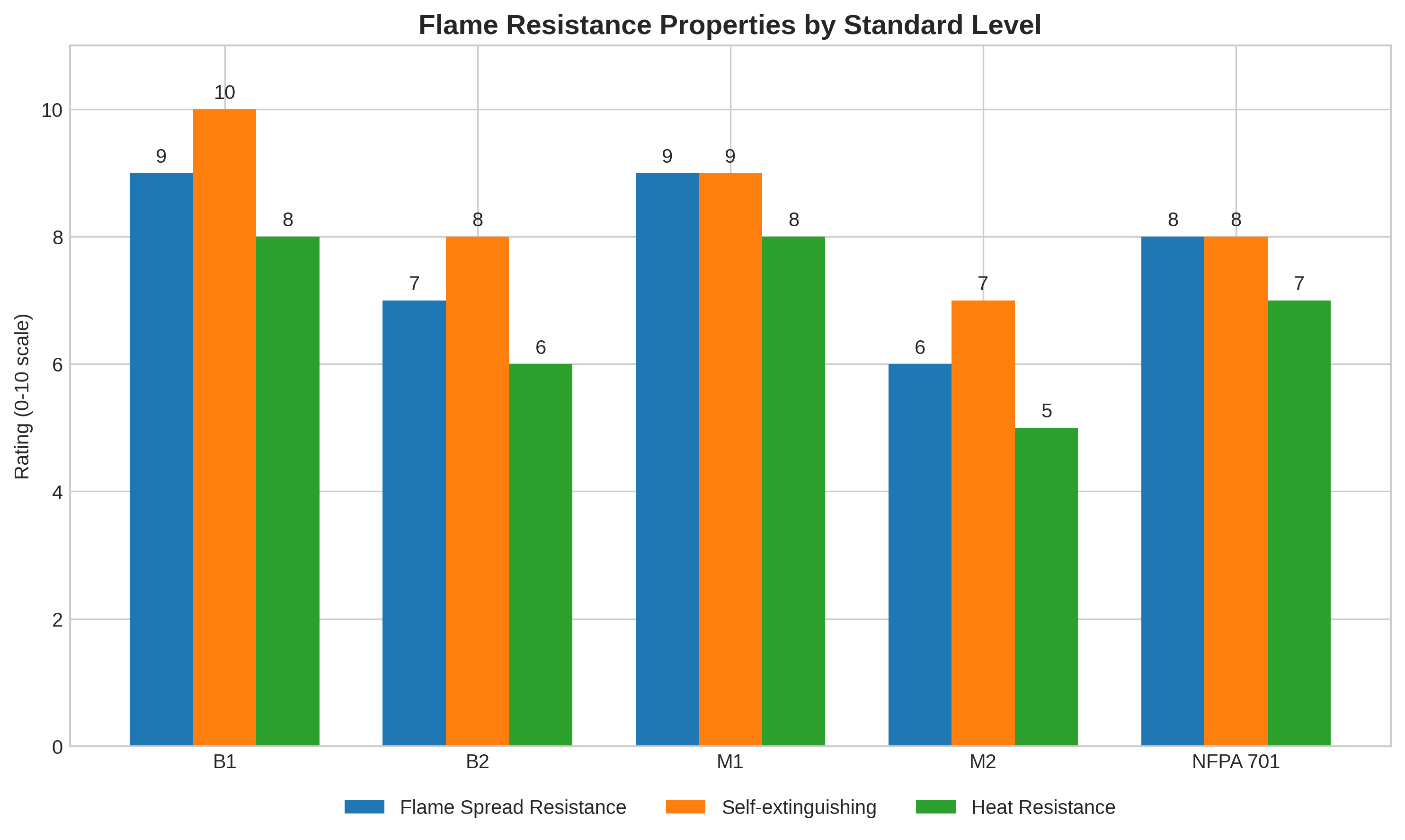

Flame Retardant Levels and Requirements

| Level | Description | Requirements |

| B1 | Fire retardant, self-extinguishing | Difficult to ignite, limited flame spread |

| B2 | Normally flammable, self-extinguishing | Less fire resistant than B1 |

| M1 | Non-flammable combustible materials | Excellent fire resistance, low flammability |

| M2 | Flammable materials with low flammability | Medium fire resistance |

| NFPA 701 Test 1 | For materials ≤700g/m², single-layer fabrics | Pass flame propagation test |

| NFPA 701 Test 2 | For plastic films, vinyl-coated fabrics | Pass flame propagation test for heavier materials |

Choosing Your Protection Level

| Fire Danger Level | Best Standard | Good For… |

|---|---|---|

| High risk | B1 or NFPA 701 Method 2 | Welding areas, chemical storage |

| Medium risk | NFPA 701 Method 1 | Event tents, truck covers |

| Basic protection | General flame retardant | Temporary covers, indoor use |

Applications of Different Flame Retardant Level Materials

| Level | Common Applications | Industry Sectors |

| B1 | Public buildings, exhibition halls, theaters, hospitals | Construction, Events, Healthcare |

| B2 | General industrial use, warehouses, temporary structures | Industrial, Storage, Transportation |

| M1 | Public buildings, high-risk environments, theaters | Events, Entertainment, Public facilities |

| M2 | Commercial buildings, standard requirements | Commercial, Industrial |

| NFPA 701 | Commercial buildings, public spaces in the US | Commercial, Public facilities, Events |